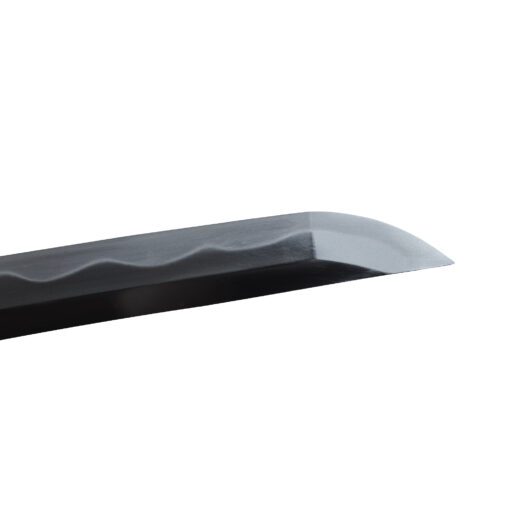

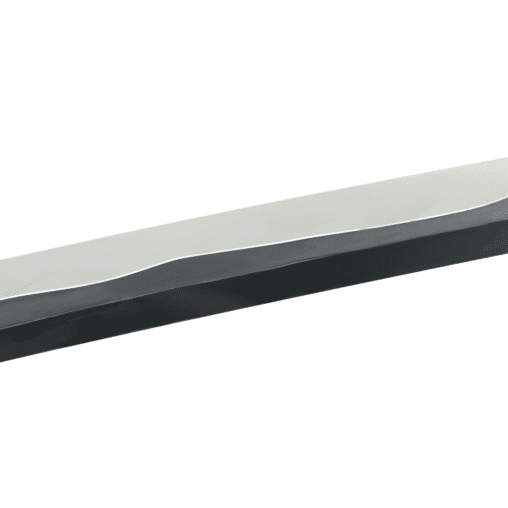

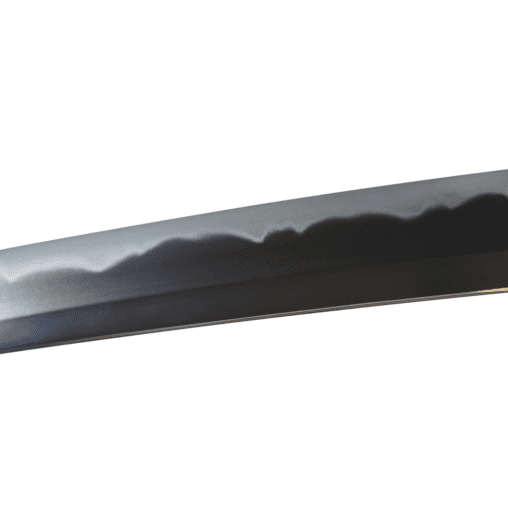

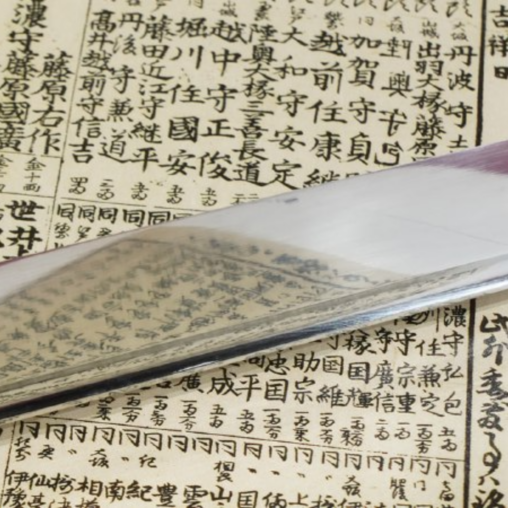

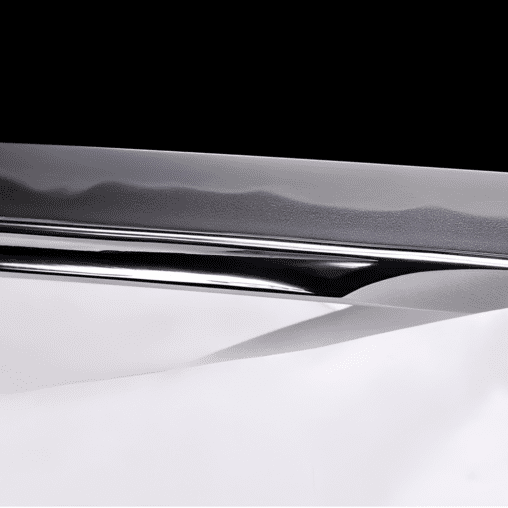

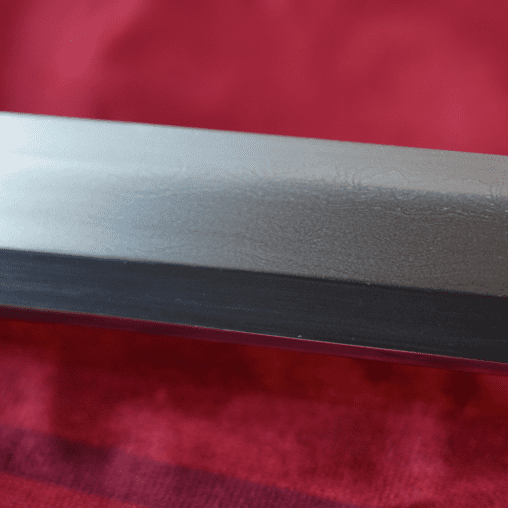

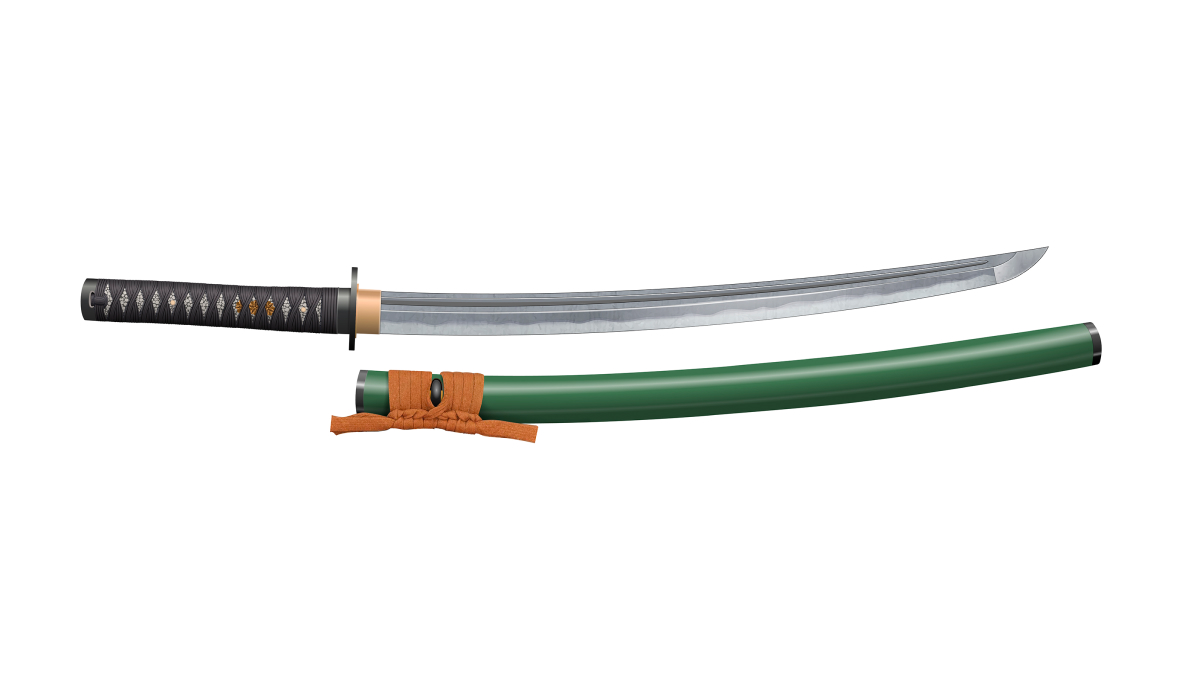

Blade

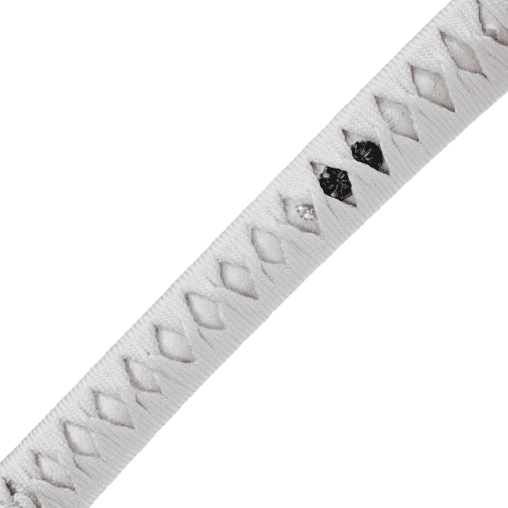

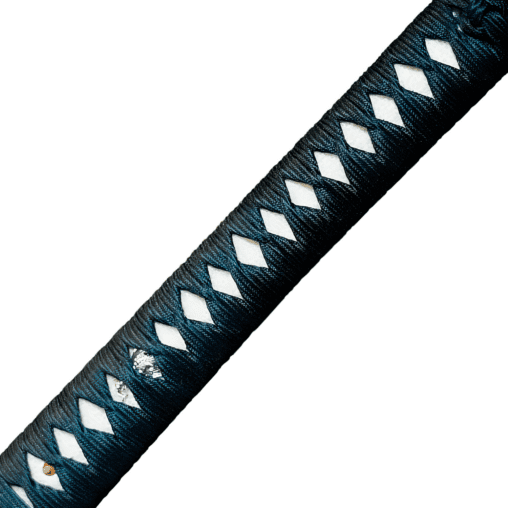

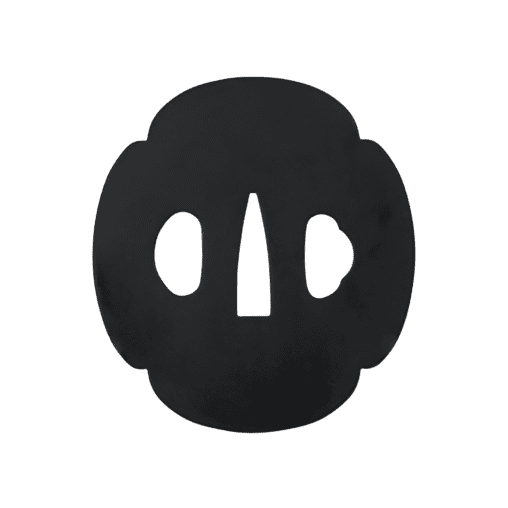

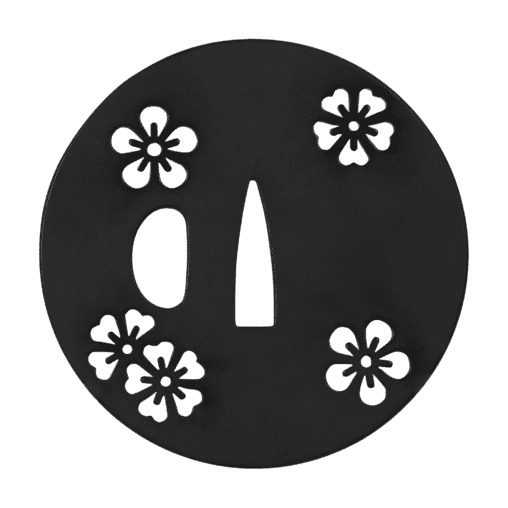

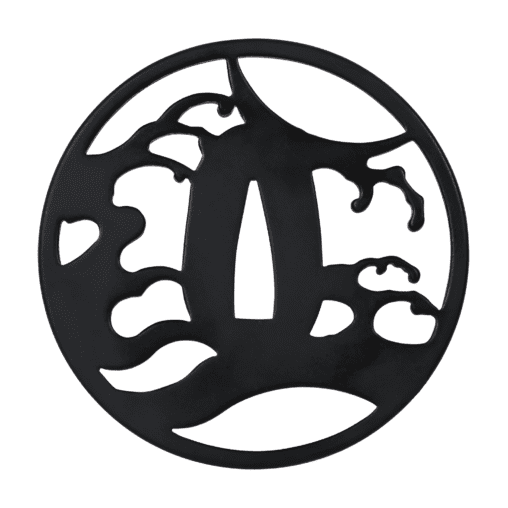

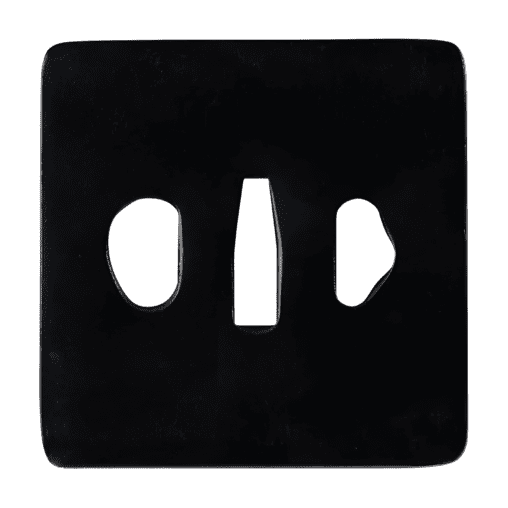

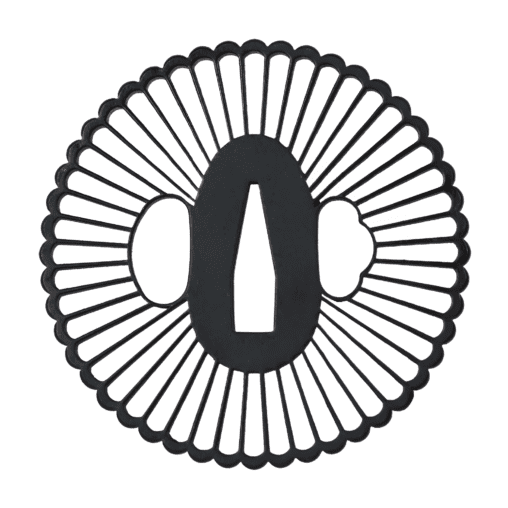

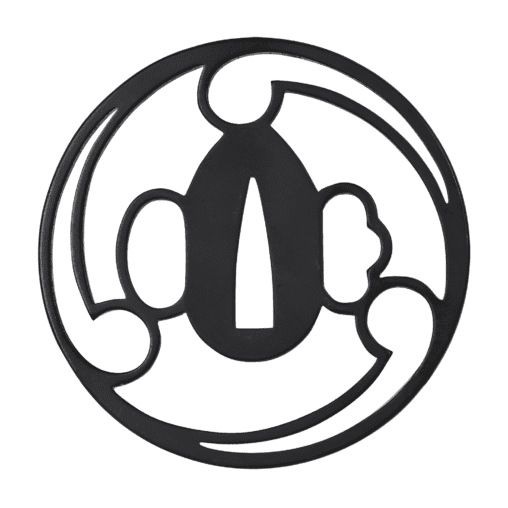

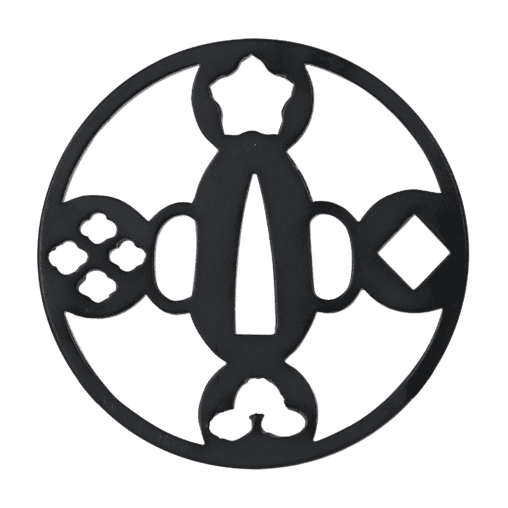

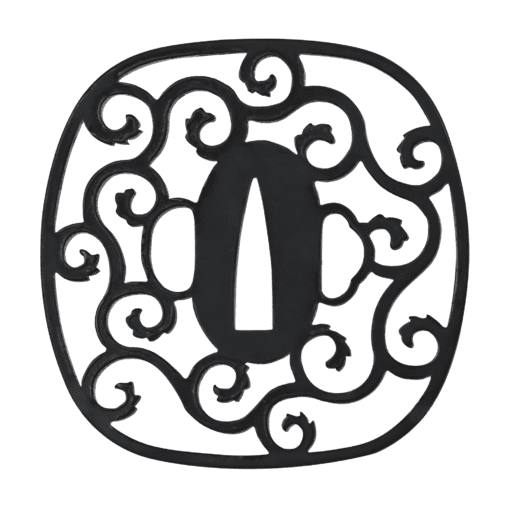

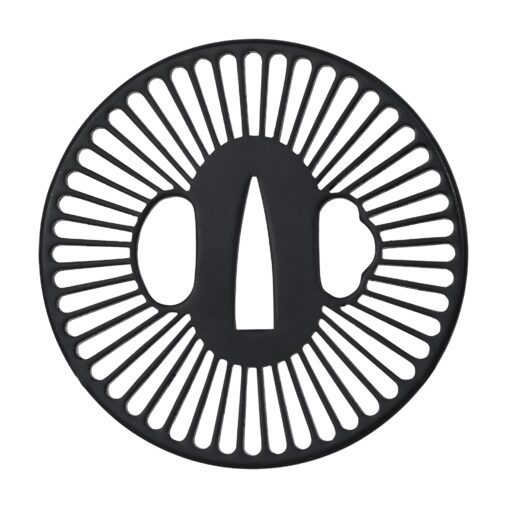

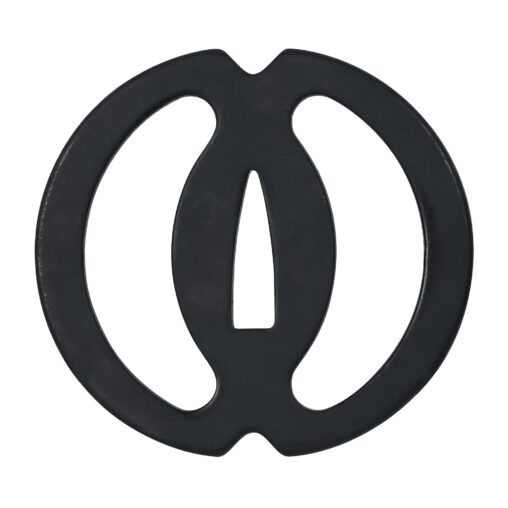

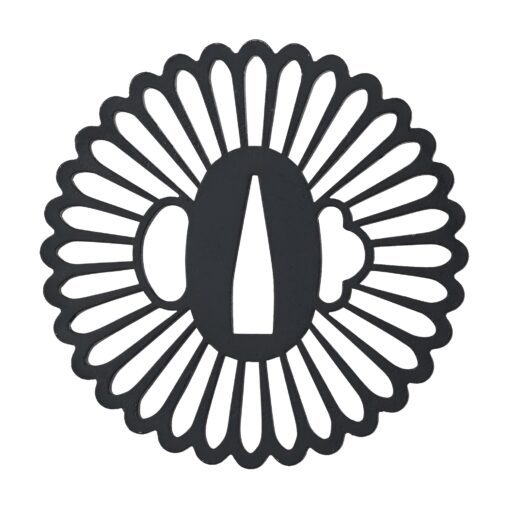

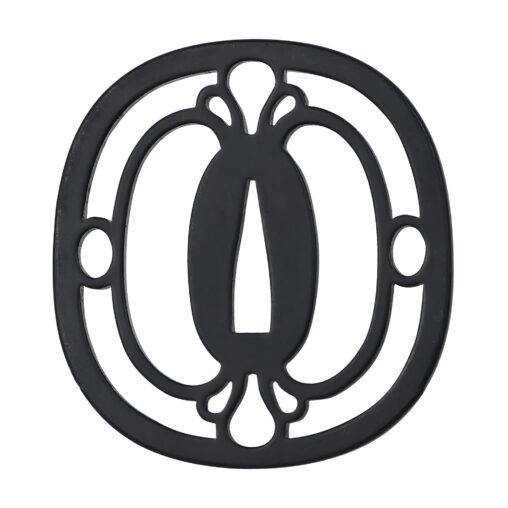

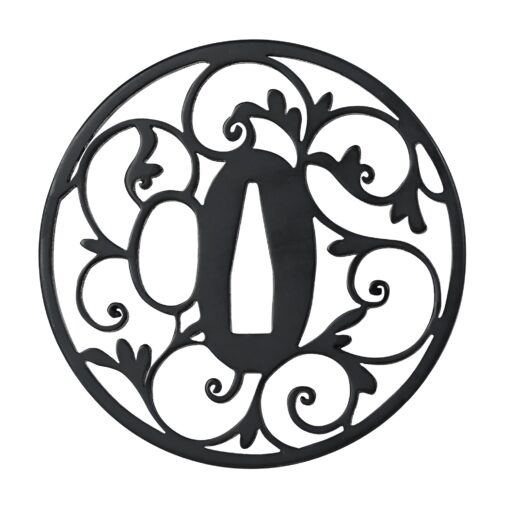

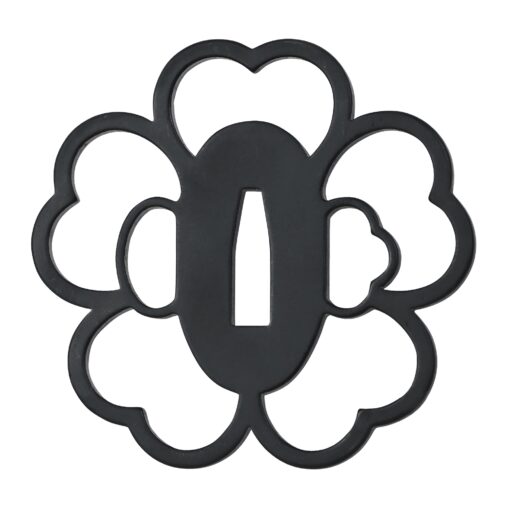

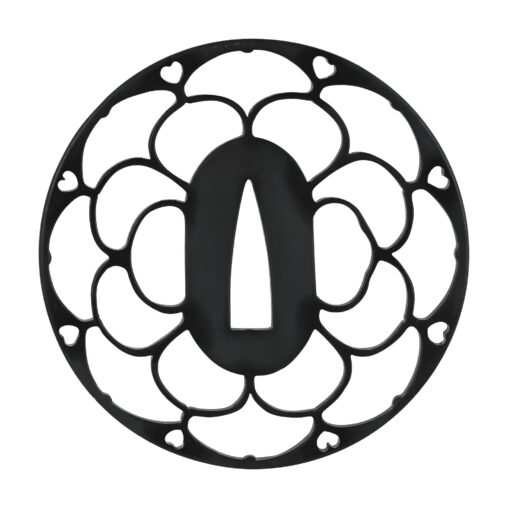

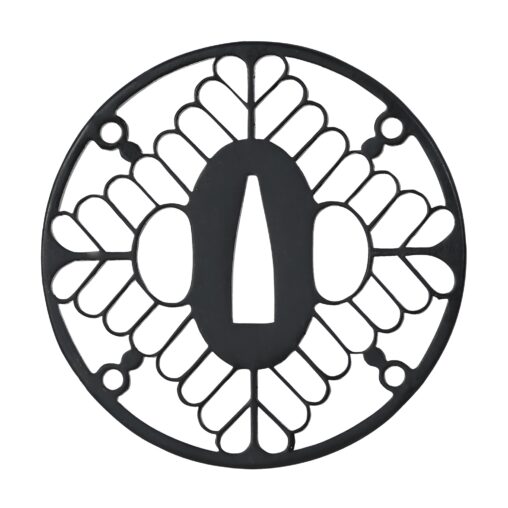

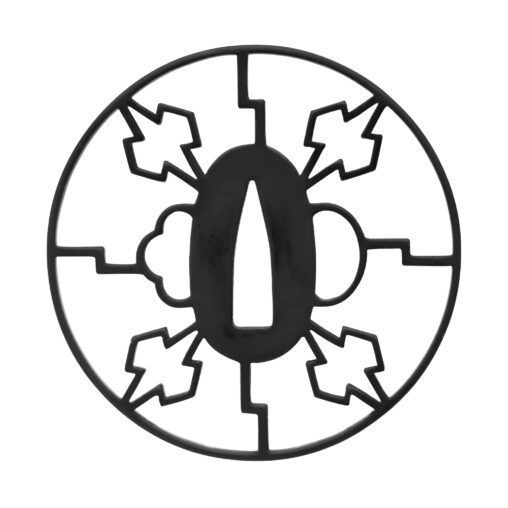

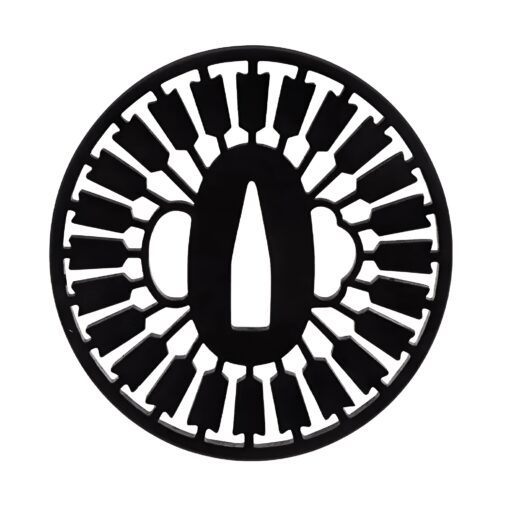

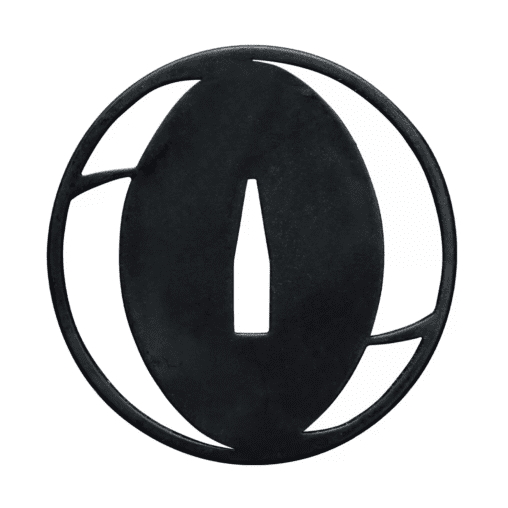

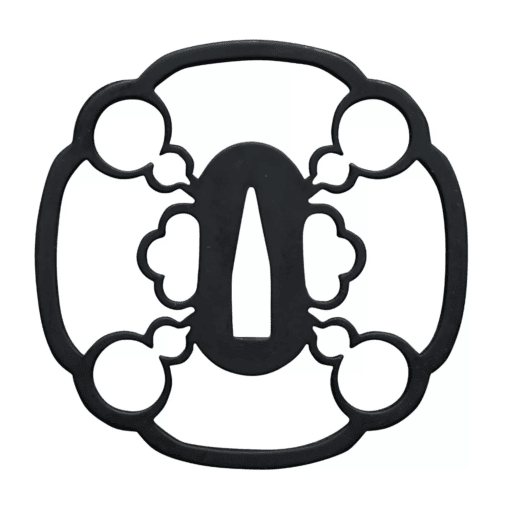

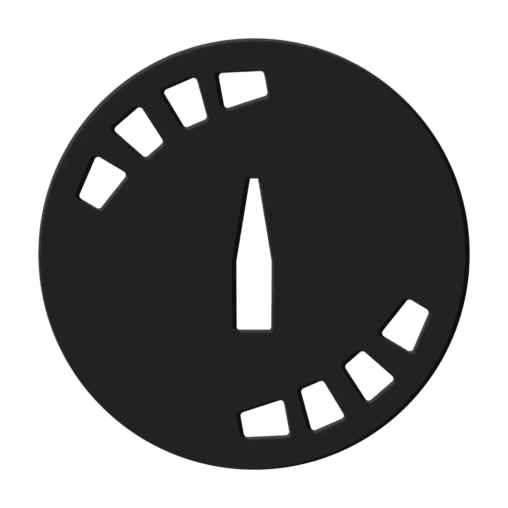

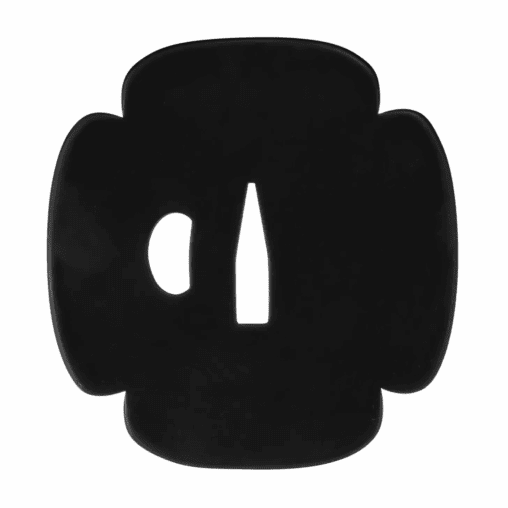

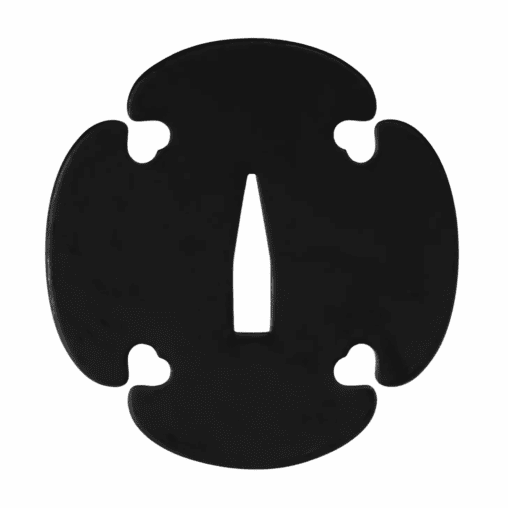

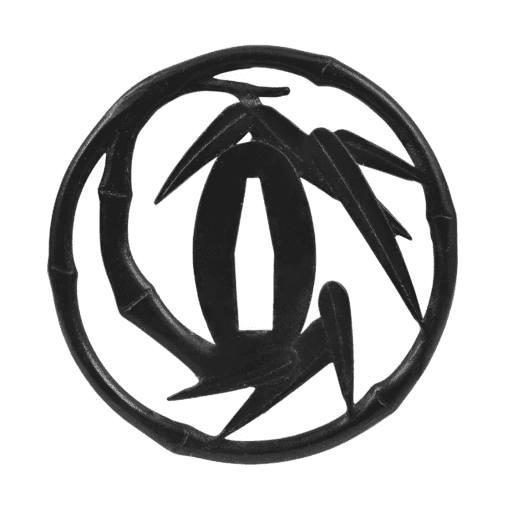

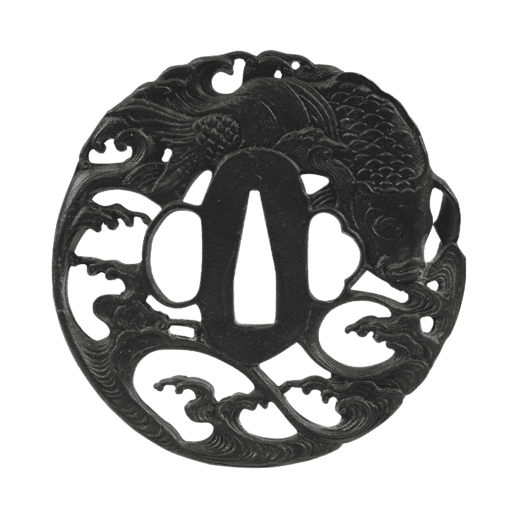

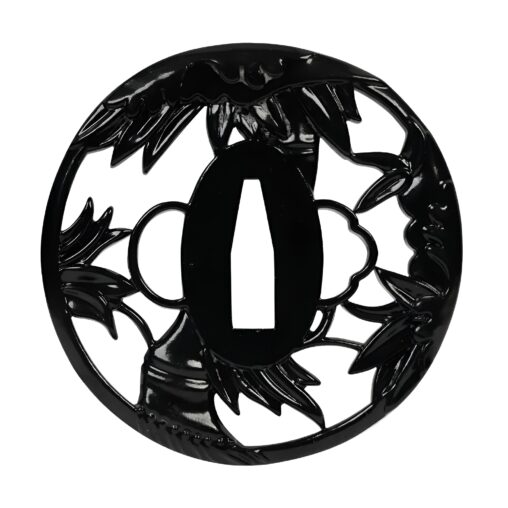

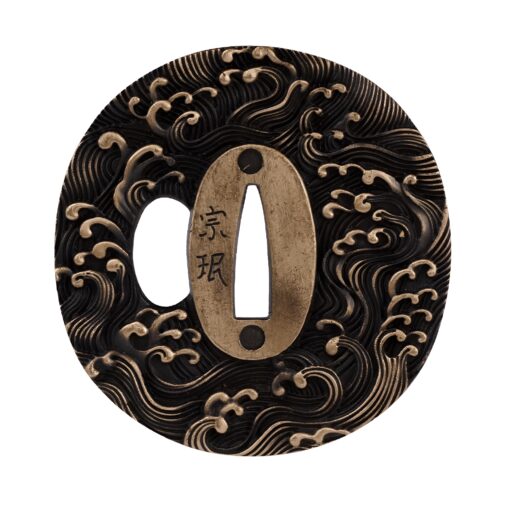

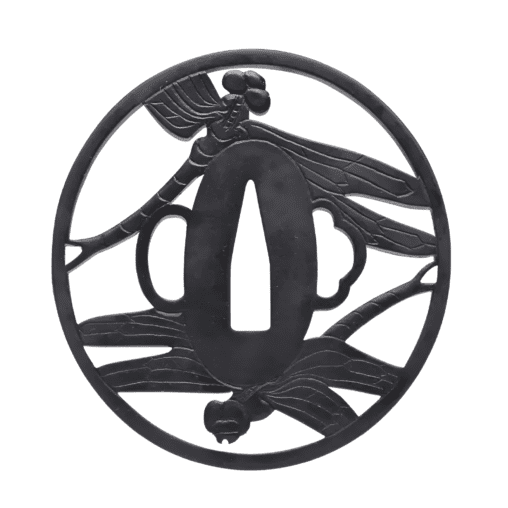

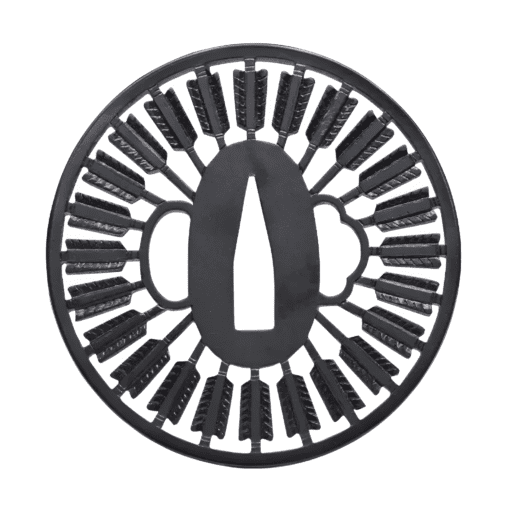

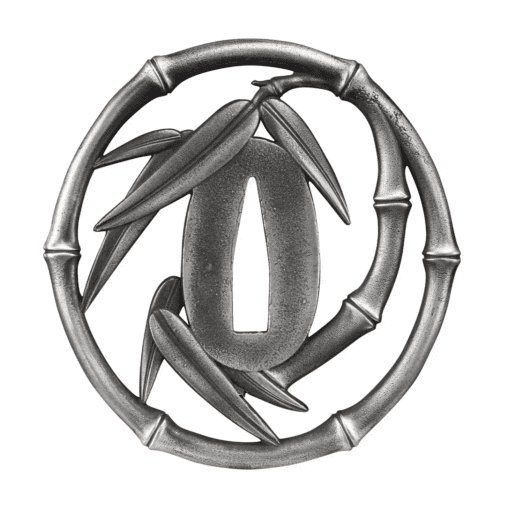

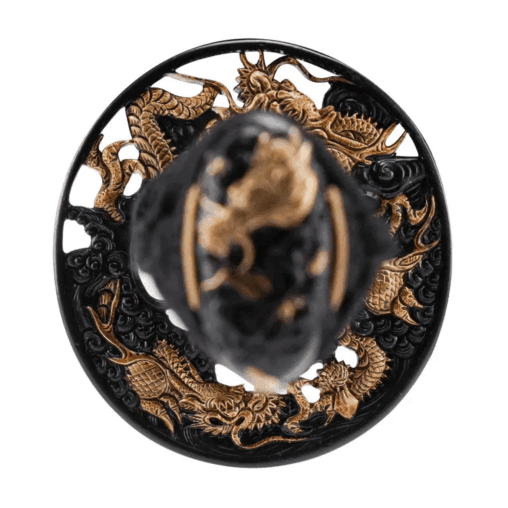

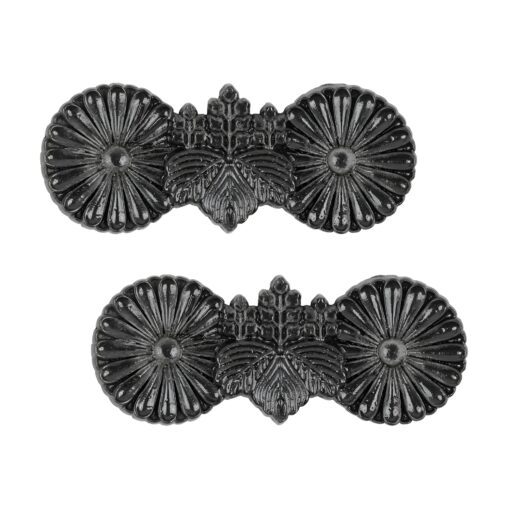

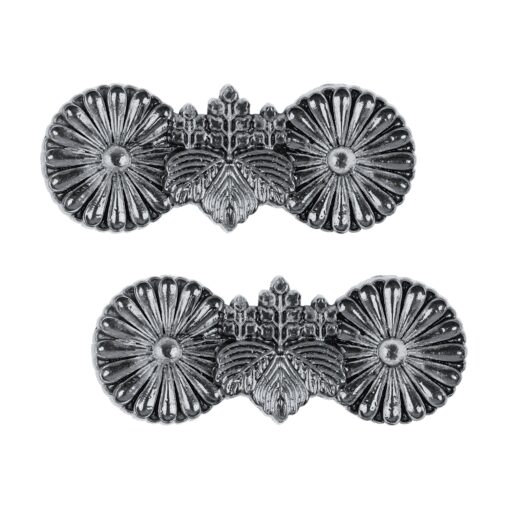

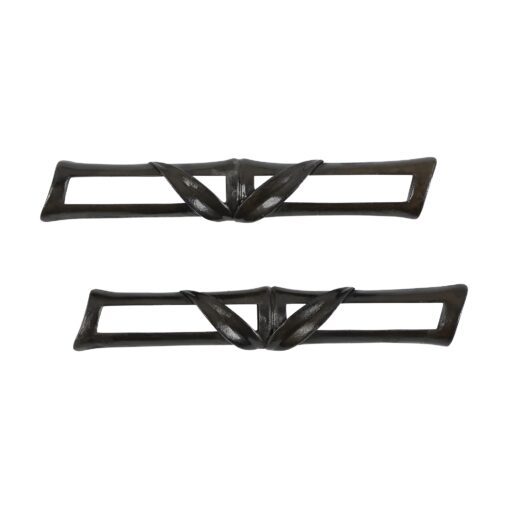

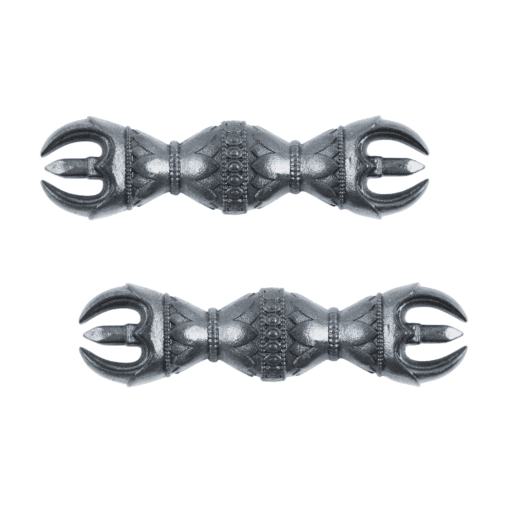

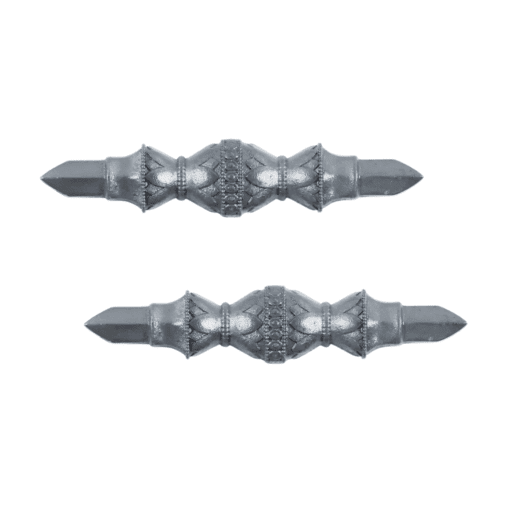

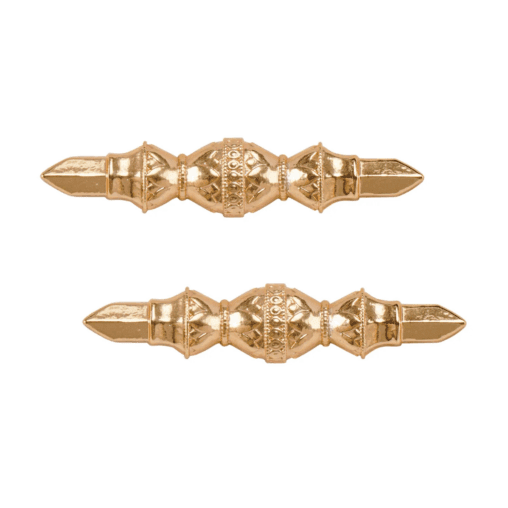

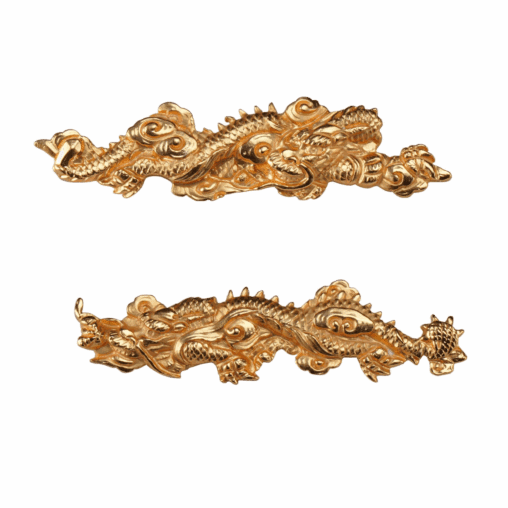

Handle/Fittings

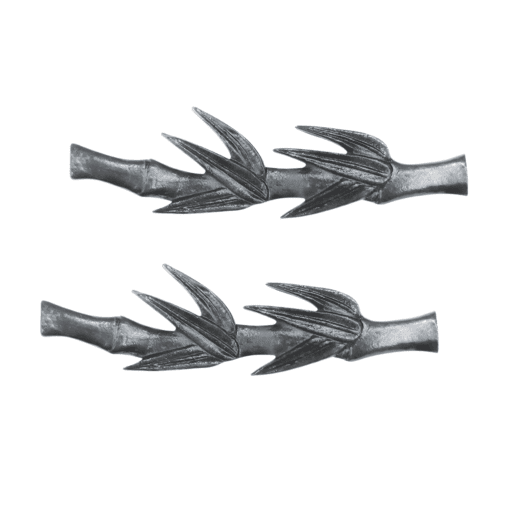

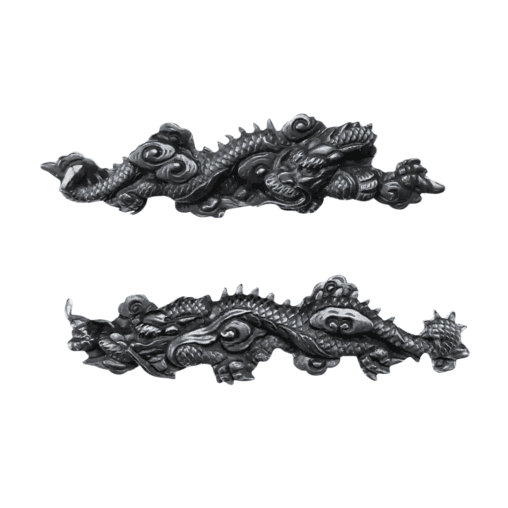

Scabbard & Extras

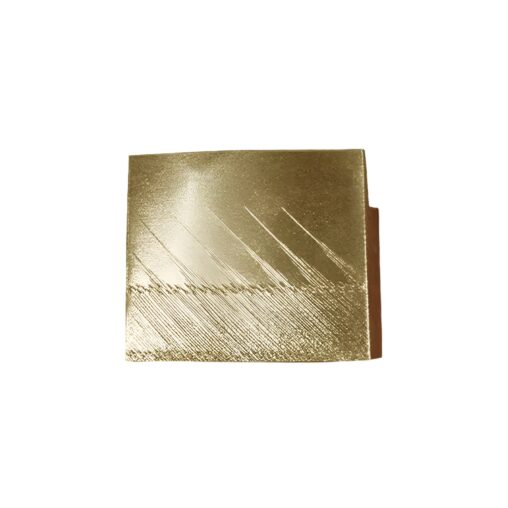

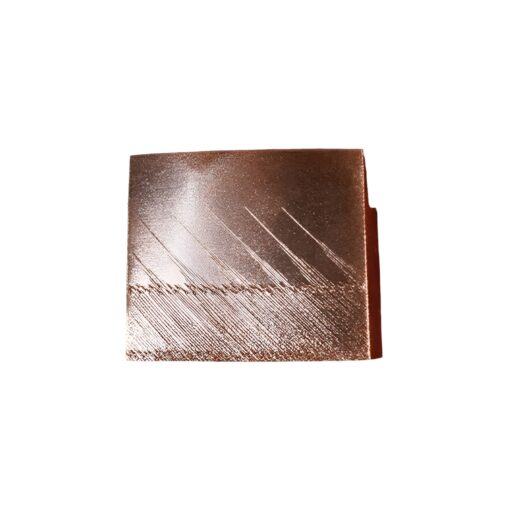

Steel Type

When choosing a sword, the type of steel is crucial depending on your intended use. Some steels are renowned for their durability or edge retention, while others have attractive patterns that are better suited for display rather than practical or combat use. To help you make the best choice, we've added detailed descriptions for each type of steel.

With 0.60% carbon, 1060 is an affordable and balanced steel. It’s less hard than higher-carbon steels, so it may not hold an edge as long, but it’s tougher and less likely to shatter, making it a cost-effective choice for bladeds with decent durability.

The 9260 spring steel, with 0.60% carbon and 2% silicon, creates a flexible and sturdy blade that can easily bend without breaking. Its rust resistance makes it ideal for both decorative and heavy-duty cutting tasks.

T8 steel is a modern industrial tool steel known for its durability and strength. Renowned for toughness, T8 excels in cutting tasks against hard targets like bamboo or tatami mats. It is also the most affordable tool steel, making it a popular choice.

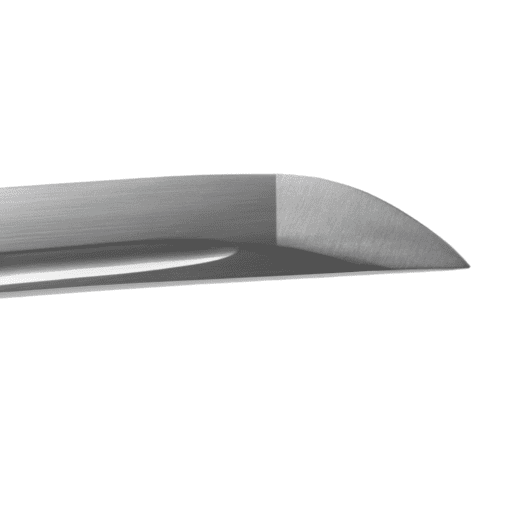

1095 high carbon steel, with a carbon content of 0.95%, is renowned for its hardness and ability to hold a razor-sharp edge. This steel excels in cutting practice due to its high blade hardness, but it is also more brittle compared to softer steels, making it less suitable for heavy impact or bending tasks. This makes it one of the most popular blades due to its excellent affordability-to-performance ratio.

The S7 Steel is known in the sword community as "shock steel" due to its ability to retain a sharp edge after rigorous and prolonged cutting activities. Essentially, it's one of the best materials for making durable swords that holds edge well.

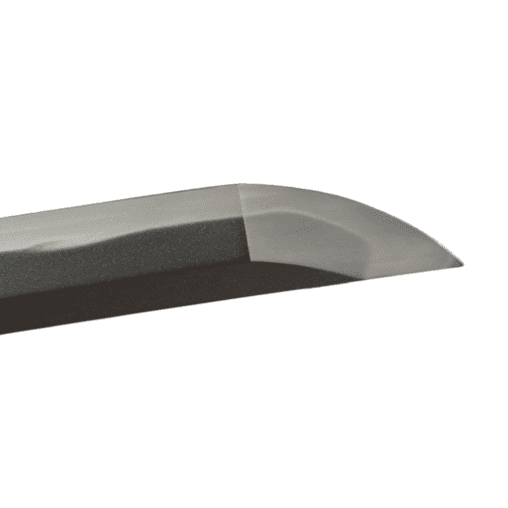

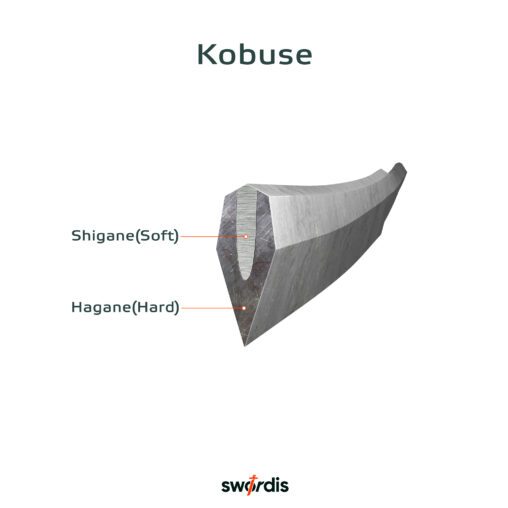

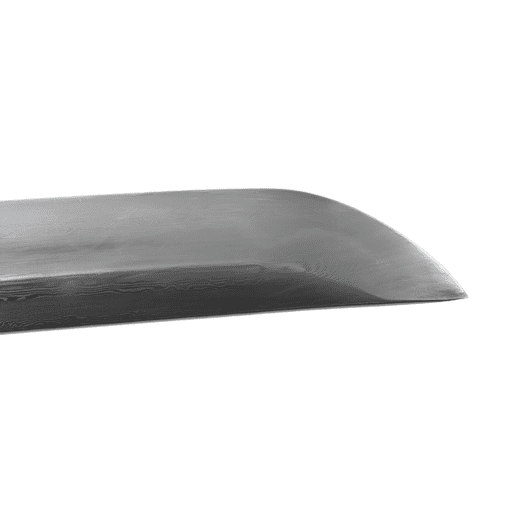

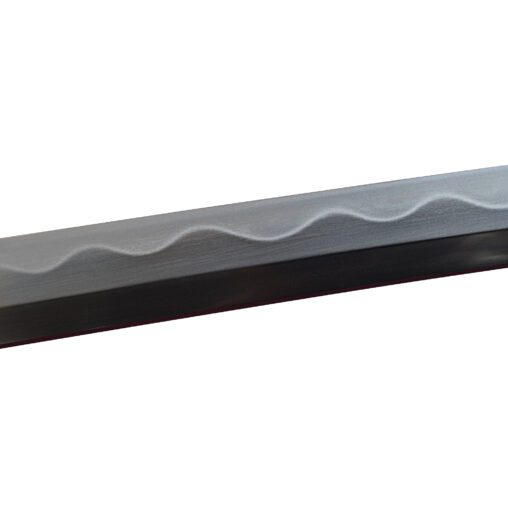

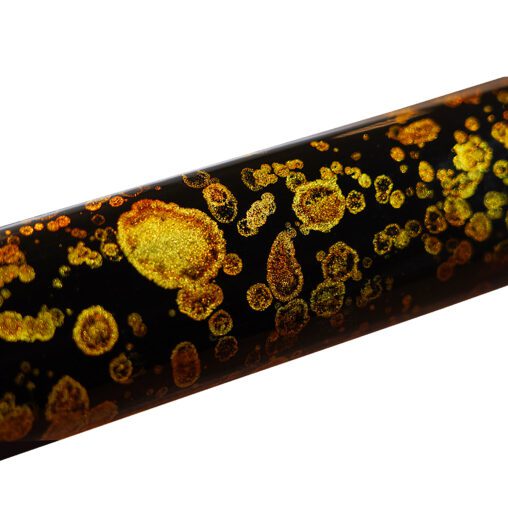

Crucible steel is a smelted steel. Unlike steels such as 1095, it develops a much more distinctive hada (grain pattern). With a carbon content of approximately 0.6%, it offers a balance of properties, providing good toughness after clay tempering while maintaining moderate edge hardness.

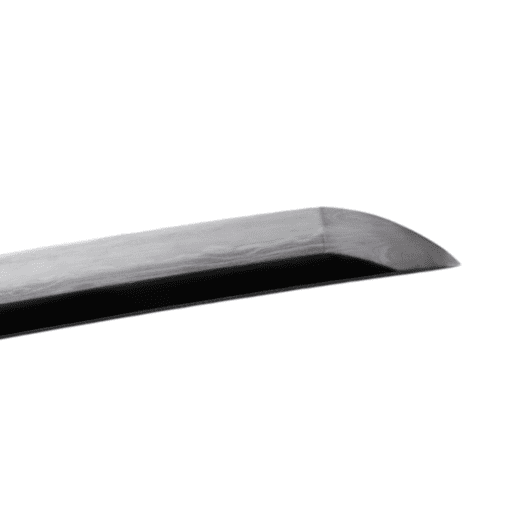

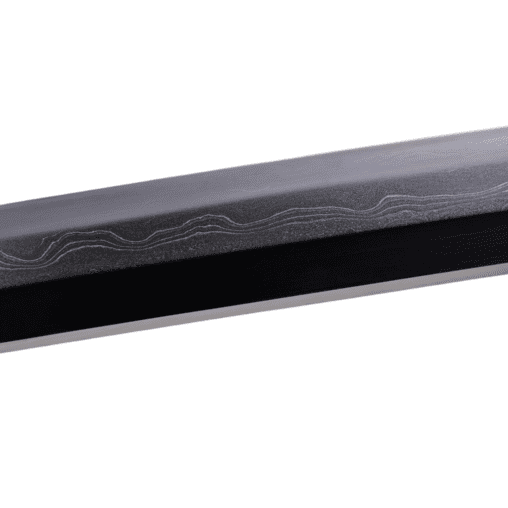

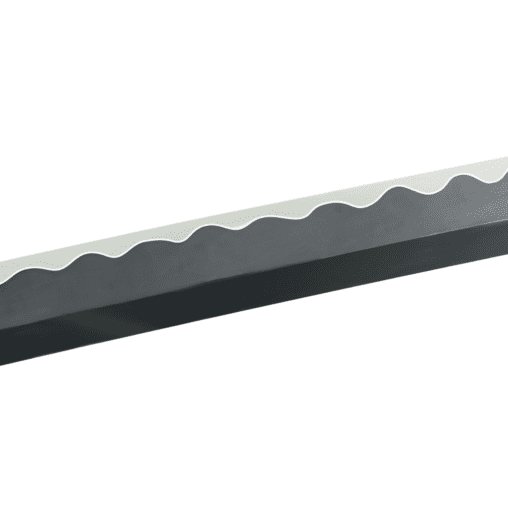

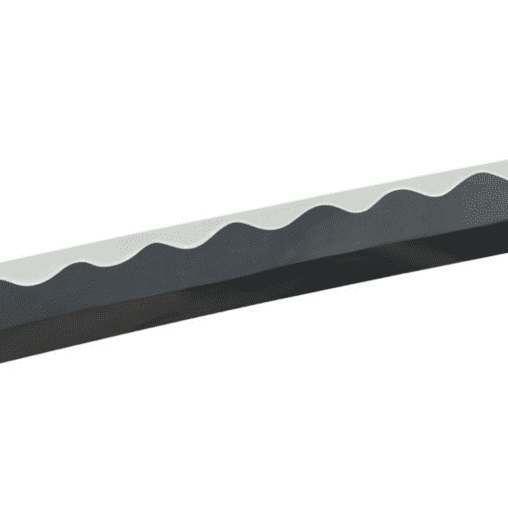

Folded steel is made by layering and folding two different types of steel - in this case, a mix of T8 Carbon steel and 9260 spring steel. The folding process creates a beautiful pattern on the blade from the contrast between the two steels. This method is inspired by traditional Japanese swordmaking techniques.

Advanced folded steel is similar to regular folded steel, but it uses a different folding method and a greater number of folds, which takes considerably more time.

Tamahagane steel is known for its strength and beauty. While traditional tamahagane steel is forged in a tatara, this version is mass produced, yet remains genuine and much more affordable.