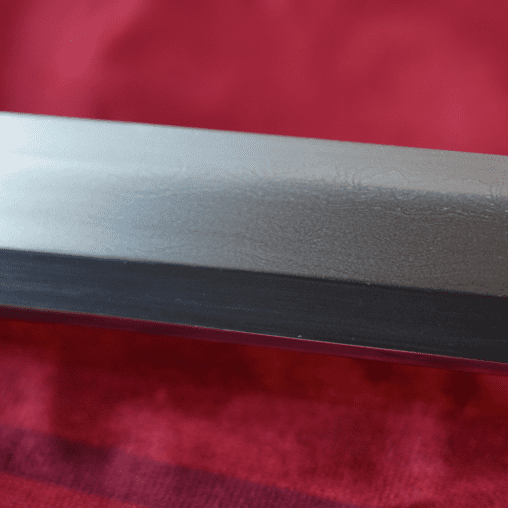

Blade

Handle/Fittings

Scabbard & Extras

Steel Type

Steel type is crucial when choosing a sword, as each has its own advantages and disadvantages. We've added descriptions for each steel to help you choose the best one for your needs.

There are some recommendations or limitations for this step because you chose

Tamahagane steel is known for its strength and beauty. While traditional tamahagane steel is forged in a tatara, this version is mass produced, yet remains genuine and much more affordable.

Length (Nagasa)

The standard length is the most commonly used length for katanas. Choosing a different length would significantly increase the production time.

There are some recommendations or limitations for this step because you chose

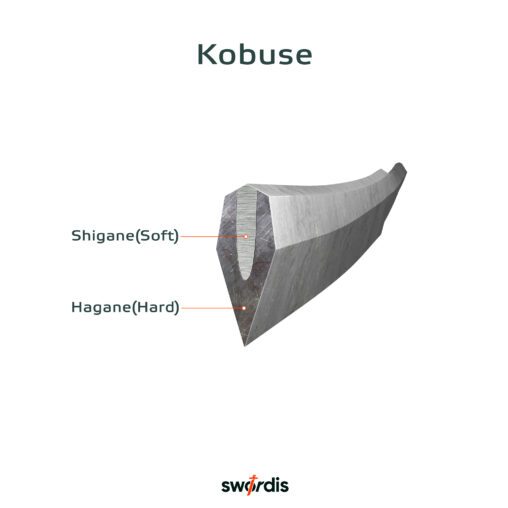

Blade Construction (Gitae)

Gitae is the core and inner structure of the Japanese katana, involving various layers and types of steel traditionally used to enhance the sword's strength, flexibility, and cutting ability.

There are some recommendations or limitations for this step because you chose

Maru-gitae is a traditional Japanese method where a single type of medium to high carbon steel is shaped into a blade. The distinctive hardness variation between the blade's edge and body is achieved solely through heat treatment.

The "sanmai," or "three-layer forging", involves a high carbon steel core and edge, flanked by tougher steel layers for support. This design allows extensive polishing without exposing the softer core at the edge.

Kōbuse construction, or "armor-covered," involves wrapping a softer core steel with a high-carbon shell to create a durable, sharp blade. This method enhances the blade’s edge and strength by forming martensite crystals.

The hon-san-mai construction uses three types of steel for the inner core: the softest at the spine, medium on the sides, and hardest at the edge.

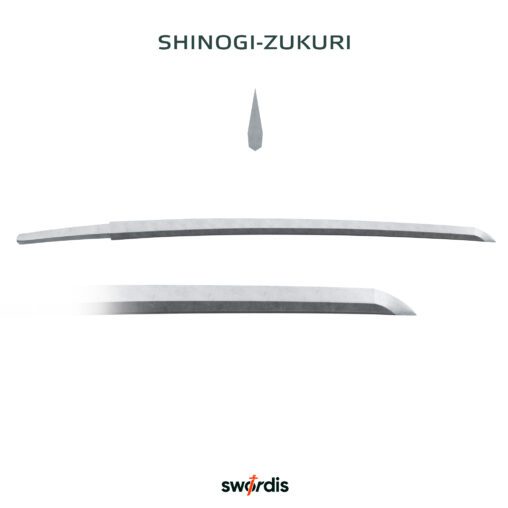

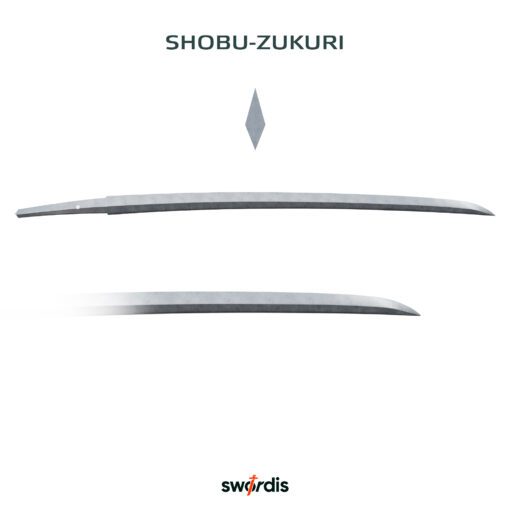

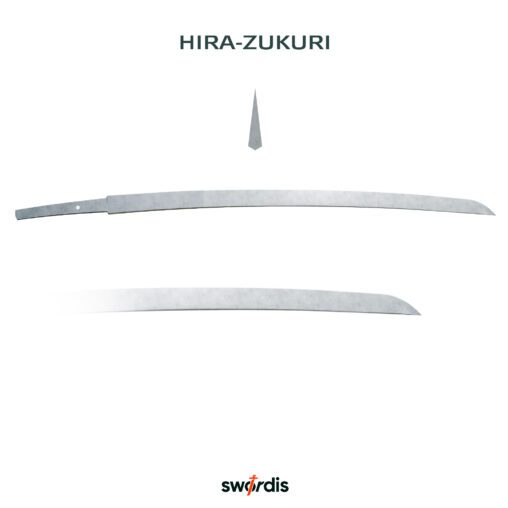

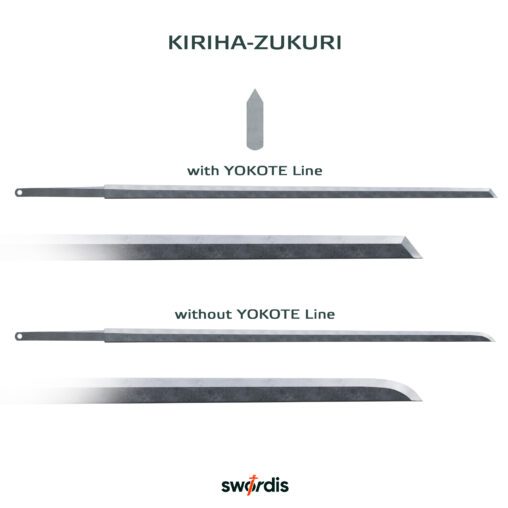

Blade Shape (Zukuri)

The Japanese katana sword comes in various blade shapes, known as zukuri. These shapes not only influence the sword's appearance but also affect its cutting ability. Opting for a shape other than Shinogi-Zukuri increases the processing time of the sword.

There are some recommendations or limitations for this step because you chose

The Shinogi-Zukuri style, used in 90% of katanas, features a prominent ridge line (shinogi) for added thickness. It has a curve for easier unsheathing with the ridge line near the spine for a sharper profile.

Shobu-Zukuri has a diamond shape similar to Shinogi-Zukuri but without a well-defined point separating the blade from the kissaki zone.

Opposite the Shinogi-Zukuri is the Hira-Zukuri, which features flat blades on both sides without a shinogi ridge line running across its center.

The Nagamaki-Zukuri style features a central ridge line and a large groove near the handle, making the sword lighter and more flexible. Common in katanas and heavier nagamaki swords, this design was made for sweeping strikes against armor and cavalry.

The Unokubi-Zukuri style is similar to the Kanmuri-Otoshi-Zukuri, but it is distinguished by a thickened back near the kissaki (tip of the blade). This style features a more pronounced curvature and a broader, heavier blade, which provides greater impact during slashing in tameshigiri (cutting practice).

The Osoraku-Zukuri blade profile is favored for shorter blades like the tanto dagger. It features a slender base that broadens significantly towards the kissaki (tip). This style often includes a ridgeline along its length with a yokote (tip transition point) near the midpoint, optimizing the blade for powerful cuts.

The katakiriha-zukuri style looks unorthodox because it combines two different types of zukuri blades. One side of the blade is flat, featuring a hira-zukuri shape, while the other side has a shinogi ridge line running its entire length.

The Kanmuri-Otoshi-Zukuri is a distinctive blade profile with a single edge and a spine that thickens and widens towards the tip. It lacks a yokote line at the kissaki (tip) and features a continuous ridgeline from the guard to the tip. Some variations include a fuller near the thickened portion of the blade for better balance. Although this shape is complex, it allows for stronger thrusting attacks.

This is the oldest style of the Japanese zukuri shape, frequently seen on ancient Japanese single-edged swords known as chokuto. This same zukuri style, without a yokote line, would be similar to Shinogi-Zukuri but with the shinogi ridge line running very close to the cutting edge.

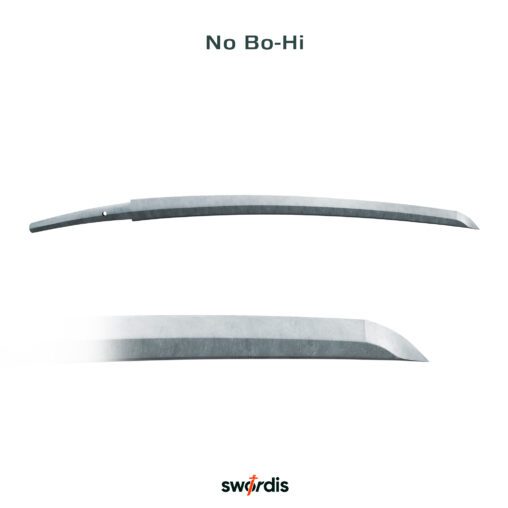

Groove/Fuller (Bohi)

Depending on what zukuri you choose, you would have some restrictions on what bo-hi you can choose due to the blade's geometry. Some geometries don't allow for any kind of bo-hi due to their thin steel parts or overall design. Additionally, some zukuri styles have a standard bo-hi that we recommend.

There are some recommendations or limitations for this step because you chose

A flat Japanese katana blade without the presence of a bohi (groove). This makes the blade slightly heavier as well as intact with its original structure. It is preferred by some for harder tameshigiri (cutting practice) targets.

The Bo-Hi is a groove/fuller that is located near the spine of the blade. It significantly lightens the blade by removing some metal without compromising its structure or integrity. This results in a louder tachikaze (sound of slashing).

The Bo-Hi with Soe-Hi features a thick groove close to the spine accompanied by a second, thinner groove under the ridge line.

The Naginata-Hi, a type of Bo-Hi groove, is named after its common appearance on naginata polearms. Positioned near the hilt, this groove is shallow yet deep and relatively short. It enhances the blade's aesthetic and reduces its weight.

Tang Groove/Fuller (Nakago-Hi)

At this step, you have the option to choose the style of the nakago-hi, which refers to both how it ends and its shape near the nakago. It can either stop just before the nakago or continue into it, with various style options available.

There are some recommendations or limitations for this step because you chose

The Kakinagashi is a type of groove that extends from the blade and ends somewhere at the mid-point of the nakago (blade tang) or just above the mekugi-ana (opening for the peg).

The Kakitoshi is similar to the Kakinagashi-hi. It is a regular type of blade groove that does not end near the mekugi-ana (opening for the peg). Instead, it extends all the way to the end of the blade tang.

Marudome is a customizable hi (groove) option where the groove starts with a rounded design. This enhances the blade's aesthetics by giving the hi a smoother and more visually appealing beginning.

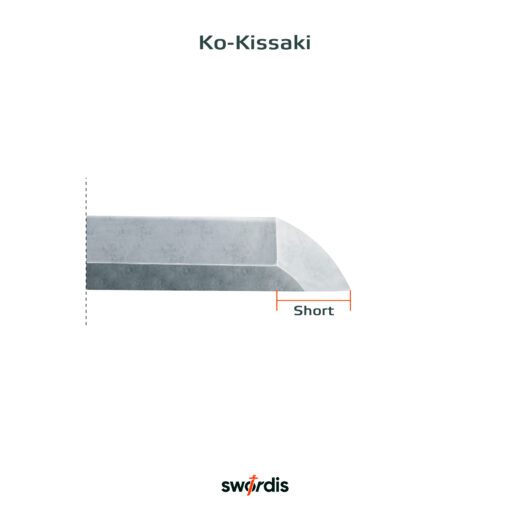

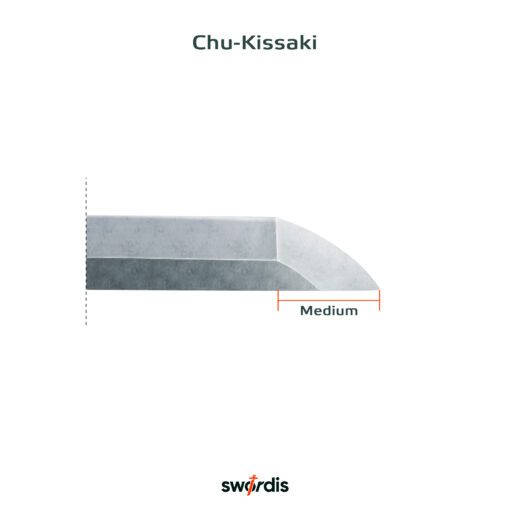

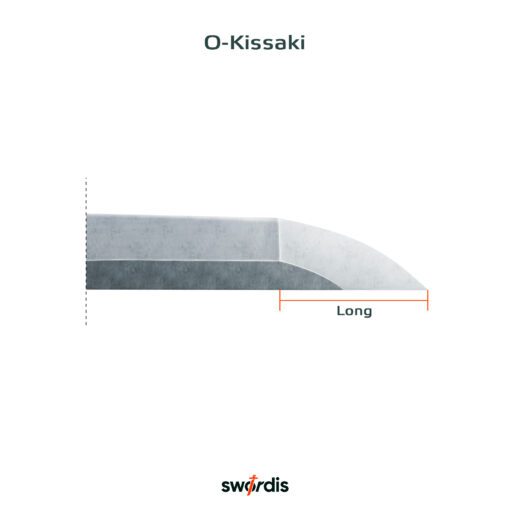

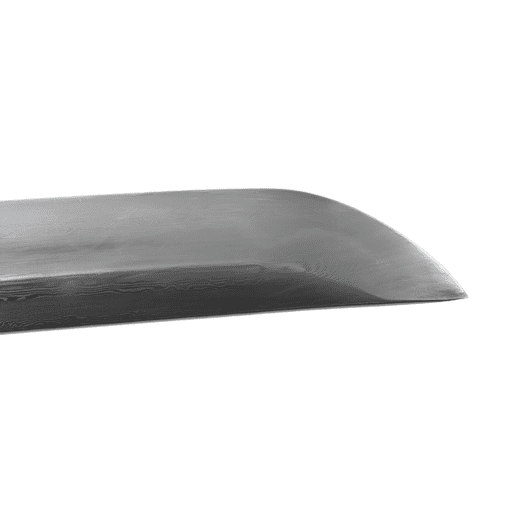

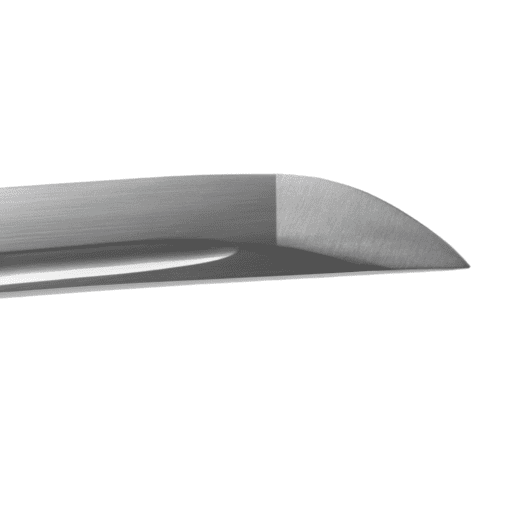

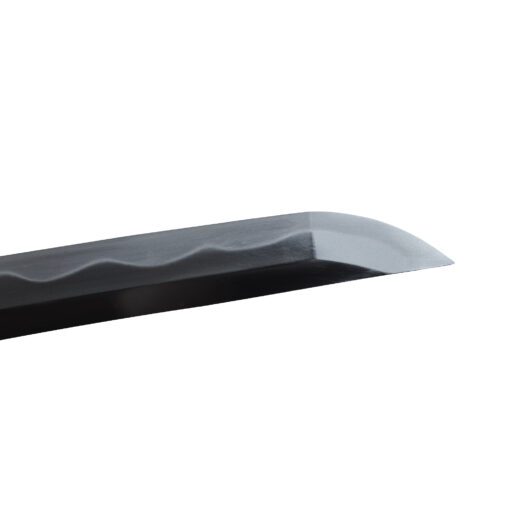

Blade Tip (Kissaki)

The kissaki options are generally limited by the katana's shape (zukuri). The only zukuri that allows you to choose any size of kissaki is shinogi-zukuri.

There are some recommendations or limitations for this step because you chose

The Ko-Kissaki is the smallest version of a katana's blade tip. It is shorter in dimensions, narrower towards the tip, and thinner in proportion.

The Chu-Kissaki is the medium, average-sized katana blade tip, commonly used throughout history. Often paired with the shinogi-zukuri blade profile, it typically measures 1.1 to 2.3 inches (3-6 cm) in length, with standard thickness and width.

Tip Point Line (Yokote)

The Yokote is the distinctive transition line separating the body of the blade from its tip, creating a visual and physical separation.

There are some recommendations or limitations for this step because you chose

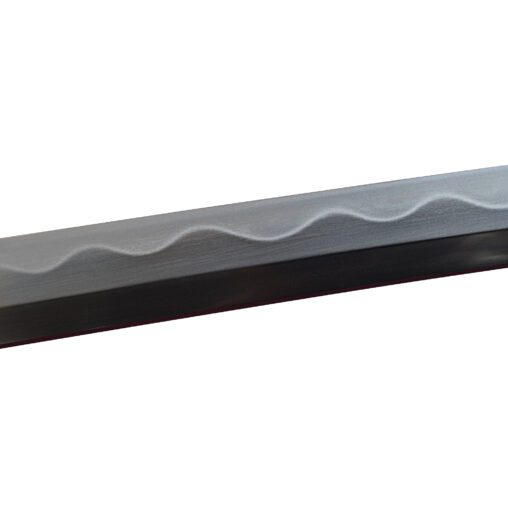

Temper Line (Hamon)

One iconic feature of the Japanese samurai katana is the hamon, a temper line created by applying clay to the blade's edge during the final forging steps. This process makes the edge harder while keeping the spine flexible. Real hamon options are available only with clay-tempered steel, while etched hamons are possible with other types of steel.

There are some recommendations or limitations for this step because you chose

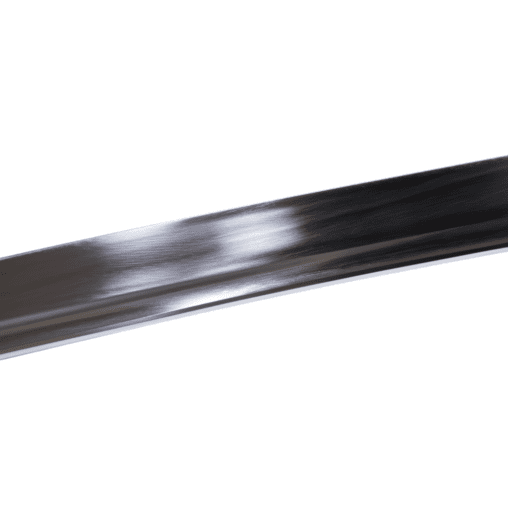

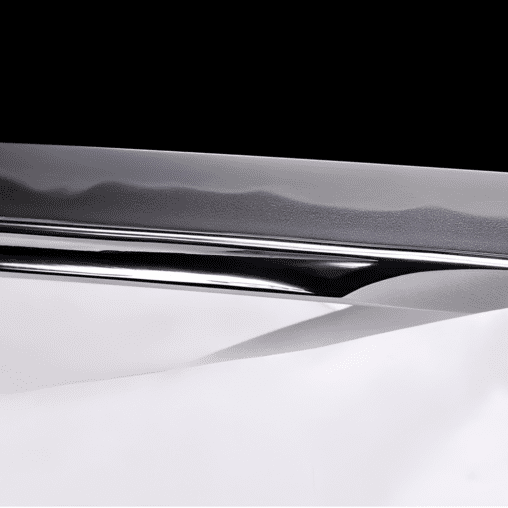

Blade Polish (Togi)

Each katana blade undergoes a hand polish, known in Japanese as togi. This final refining step removes all the imperfections produced during its crafting process. Each traditional polish stays true to authentic methods and reveals the blade's best attributes. This masterful and time-consuming process can take weeks or months to complete.

There are some recommendations or limitations for this step because you chose

This is a long polishing process with a high attention to detail. It makes the katana's blade shinier and more reflective than regular mirror polishing.

The Sashikomi A polish is a traditional katana blade polishing method that highlights the blade's details, such as the temper line and grain.

Sashikomi A+ polishing is the advanced level of traditional polishing, enhancing the visibility of the temper line and the blade's grain.

Tang Inscription (Mei)

A signature can be added to the tang, located beneath the handle, where swordsmiths traditionally inscribe their name and the date of the blade. Choosing a custom mei allows us to inscribe anything you wish on the tang, but it will be added with Kanji characters, to honor its creators. Please make sure that your custom mei is written in Kanji characters.

There are some recommendations or limitations for this step because you chose

Tsuka Length

The standard length is the most commonly used length for katana handles. Choosing a different length will increase the production time with 2-4 weeks. Handle lengths for Tanto and Wakizashi are available only if you choose their matching blade lengths. These are custom made tsukas that will be made in exact and accurate proportion with all the other fittings, a difference that true veterans of the katana art can feel.

There are some recommendations or limitations for this step because you chose

Tsuka Shape

The shape of the tsuka is based on personal preference. There is no universal "better" or "worse" grip as it varies with each individual's hand size.

There are some recommendations or limitations for this step because you chose

The haichi is one of the most popular katana handle shapes. It features an inward curve from the blade's edge side, allowing for a very firm grip.

The Rikko handle shape features an hourglass design, with both sides of the handle narrowing inward. This allows for strengthened gripping and more power and control.

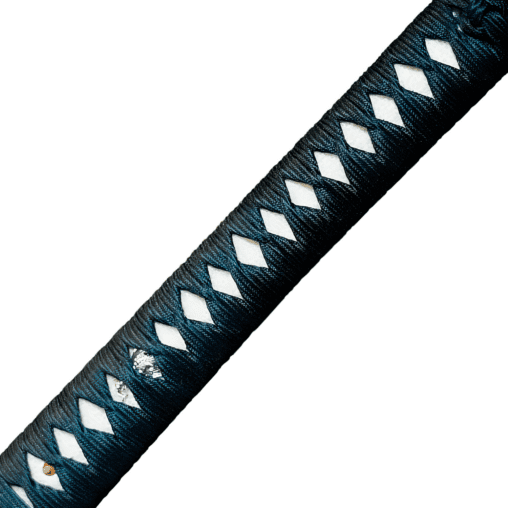

Wrapping Style (Tsuka-Maki)

There are some recommendations or limitations for this step because you chose

The Hineri-Maki is the most popular tsuka-maki (wrapping style), featuring criss-cross or diamond-shaped openings. It's found on most katanas, offering both aesthetic appeal and a firm grip for cutting practice.

Paper Wedges (Hishigami)

Hishigami are small folded paper triangles inserted into the tsuka-maki wrap to maintain its shape and provide a firmer grip. They are usually preferred and recommended for use in tameshigiri (cutting practice).

There are some recommendations or limitations for this step because you chose

A standard katana handle without the presence of paper wedges.

The presence of around 50 hishigami papers, invisible yet tightly tucked inside the handle's cord wrap.

Hishigami Pro is an advanced version often made from more durable and high-quality materials like plastic or specially treated paper. These are designed to provide even better tightness and stability for the tsuka-maki (cord wrap).

Rayskin (Samegawa)

The samegawa is a type of rayskin or sharkskin material that is wrapped around the handle's wooden core. It is visible only through the diamond openings of the tsuka-maki wrap and offers a highly non-slip surface for the hands.

There are some recommendations or limitations for this step because you chose

Rayskin Wrap Style

Choosing a full rayskin wrap style will increase the production time with 2-3 weeks

There are some recommendations or limitations for this step because you chose

Rayskin Emperor Nodes

The Emperor Node is a section of raised bumps on the rayskin (samegawa). Its size usually represents higher and better quality while offering a more enticing visual appeal.

There are some recommendations or limitations for this step because you chose

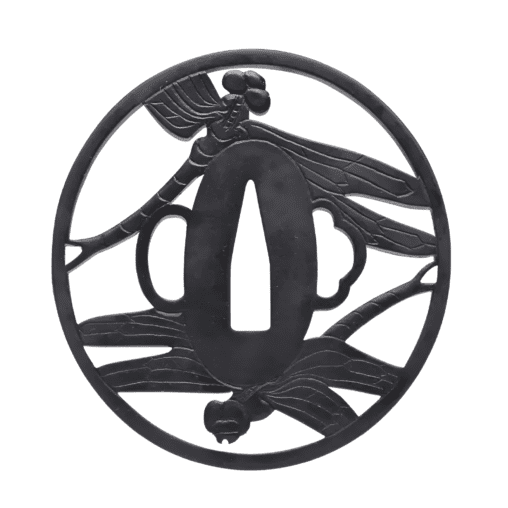

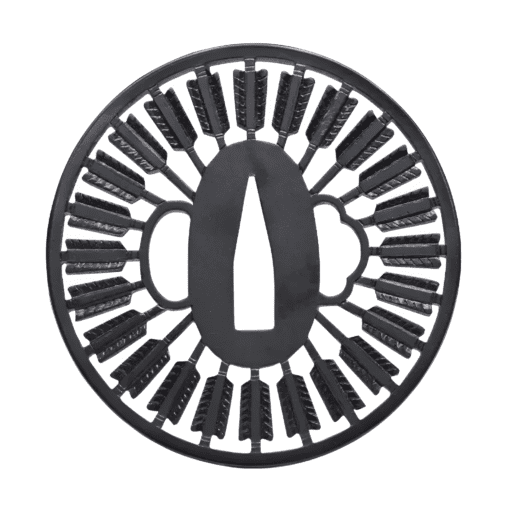

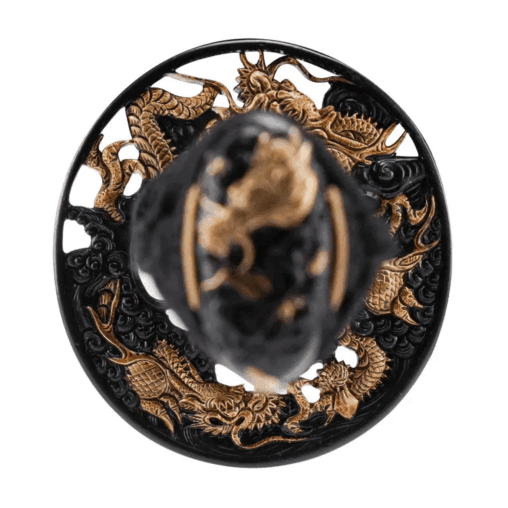

Handguard (Tsuba)

There are some recommendations or limitations for this step because you chose

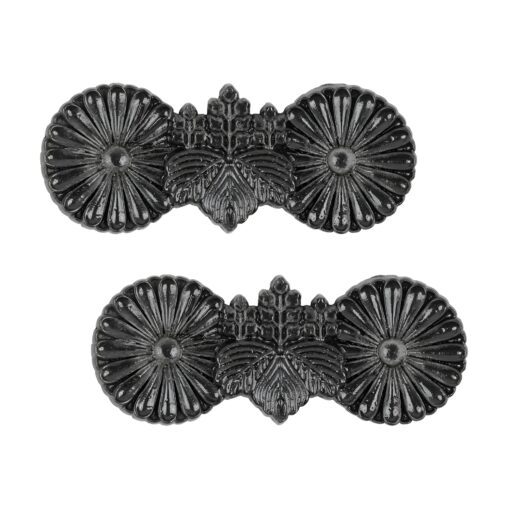

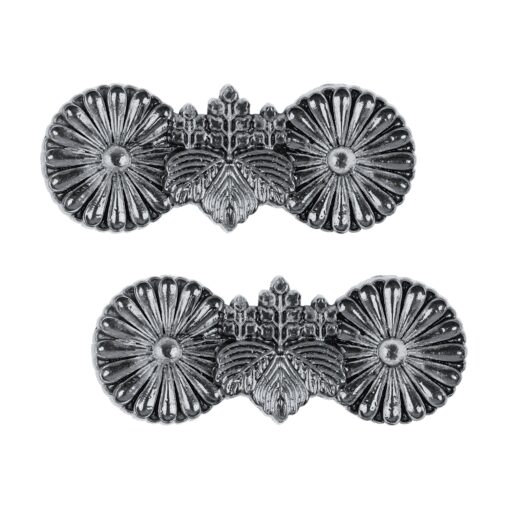

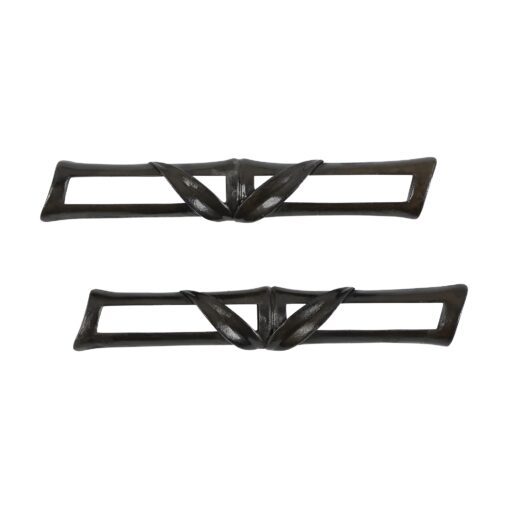

Handle Ornament (Menuki)

Menuki are small, ornate symbols placed between the rayskin and the handle's cord wrap, improving the katana's grip. Each model is available in three options: Antique Brass (goldish), Black Brass (fully black), and Cupronickel (black/silver with superior material). While at least one photo per model is provided, they all share the same pattern style but with different colors/finishes. Please use MG-01 as a reference to see the difference between antique gold and black brass.

There are some recommendations or limitations for this step because you chose

Handle Collar & Pommel (Fuchi & Kashira)

Brass fuchi and kashira typically come in a black finish by default. However, each model can be customized to feature an antique/gold finish. If you see antique gold models without photos in the portfolio, rest assured that the model will look exactly like the black version but with an antique/gold touch. Use FK-27 model as a reference to see the difference between antique gold and black brass.

There are some recommendations or limitations for this step because you chose

Spacer (Seppa)

Seppa are types of katana fittings known as spacers or washers that secure the tightness of the tsuba (guard) with the tsuka (handle).

There are some recommendations or limitations for this step because you chose

Brass Seppa is one of the most popular options due to its lighter hue enhancing the sword's aesthetics.

Copper Seppa is a popular fitting choice with a darker hue that will produce a patina over time enhancing its appeal.

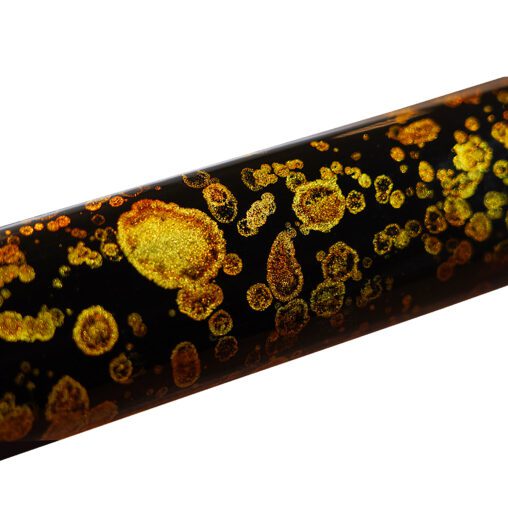

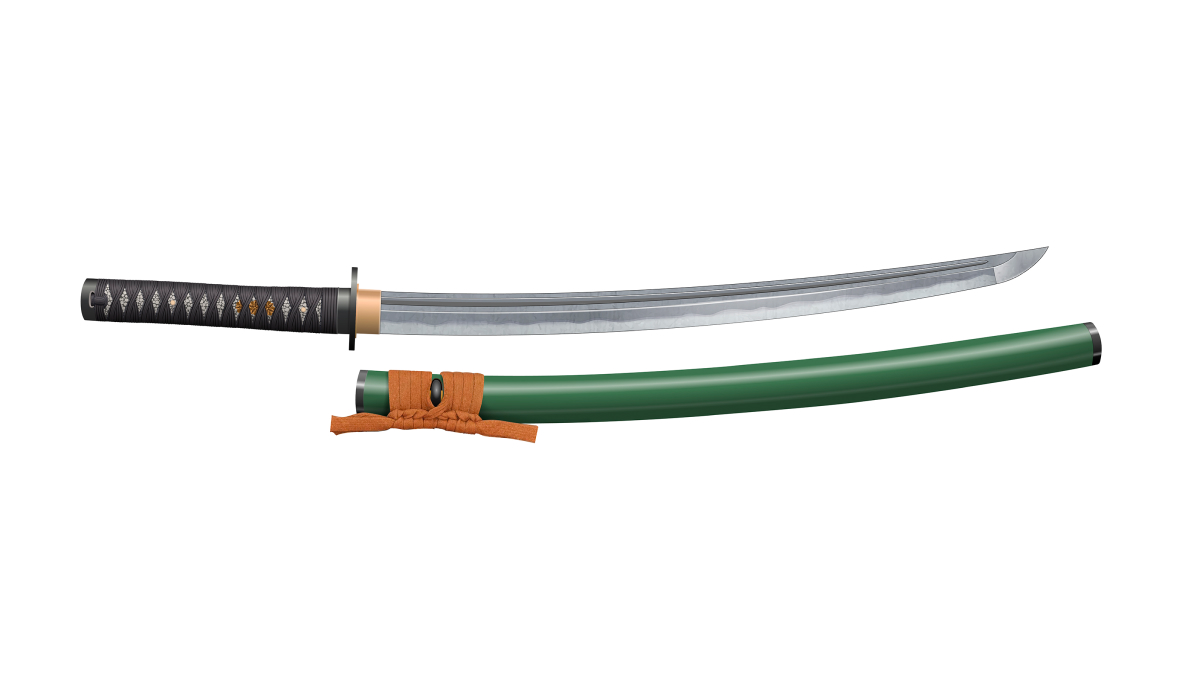

Scabbard (Saya)

Each scabbard is handmade and precisely fitted to its blade, ensuring no rattling and excellent protection against physical damage and rust, allowing for safe long-term storage. The wood can be polished for a bright reflection or finished with either an imitation or a genuine natural lacquer from an urushi tree. All scabbards come with horn parts.

There are some recommendations or limitations for this step because you chose

Cord (Sageo)

The sageo is the cord mounted on the katana's scabbard. While it enhances the visual attributes, it can also be untied and used as a belt, known as obi, used for carrying the katana in a traditional way.

There are some recommendations or limitations for this step because you chose

Upgrades

In this step, you can choose to upgrade your handle or scabbard to get closer to the perfect sword you might be looking for. This comes with considerable additional time and cost and makes the sword into the high-end spectrum. We would only recommend these upgrades if you are patient and have no budget constraints.

There are some recommendations or limitations for this step because you chose

A shirasaya is a traditional wooden case designed to protect and preserve the Japanese blade for generations—even centuries. Made to the blade’s exact measurements from untreated, unlacquered wood, it naturally absorbs moisture from the air, helping prevent rust and corrosion. This creates an ideal environment for the blade to rest safely when not in use, offering unmatched long-term protection.