17 Katanas Destructed to Find the Best Steel

NO AI USED This Article has been written and edited by our team with no help of the AI

The katana has long been a symbol of Japan, owing much of its legendary performance and artistry to the steel from which it is made from. From traditional tamahagane to modern steels, each type of steel has its own benefits.

This article explores the best steels used in katanas and their unique qualities to help you select one that matches your preference of strength, sharpness, and beauty.

The Art of Steel Selection — Why is it Important?

Selecting the best steel for a katana depends on many factors including one’s preference for the sword’s aesthetics, purpose, historical authenticity, and blade properties. In terms of performance, each steel type offers unique pros and cons that affect the blade’s properties such as:

| Property | Key Benefit | Best For |

|---|---|---|

| Strength | Prevents bending/warping | Combat swords, heavy-use blades |

| Hardness | Maintains a sharp edge | Cutting competitions, sharpness priority |

| Toughness | Absorbs shock without breaking | Functional training, high-impact training |

| Corrosion Resistance | Protects against rust/oxidation | Outdoor, display, ceremonial swords |

With these factors in mind, there truly is no “best” steel for a katana as it ultimately comes down to one’s preference.

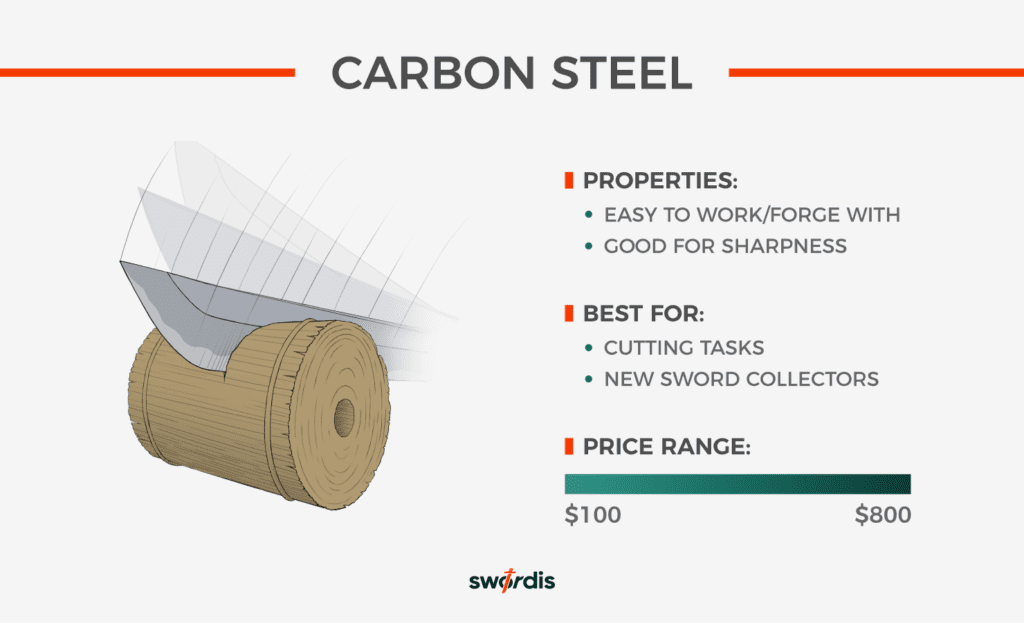

1. “Best” Overall – Carbon Steel Katana

While many Japanese sword experts may disagree, carbon steel is the “best” overall for most as it is easy to work with, making it affordable for many collectors and practitioners. These blades also have a good balance of properties, known for their strength, durability, and edge retention.

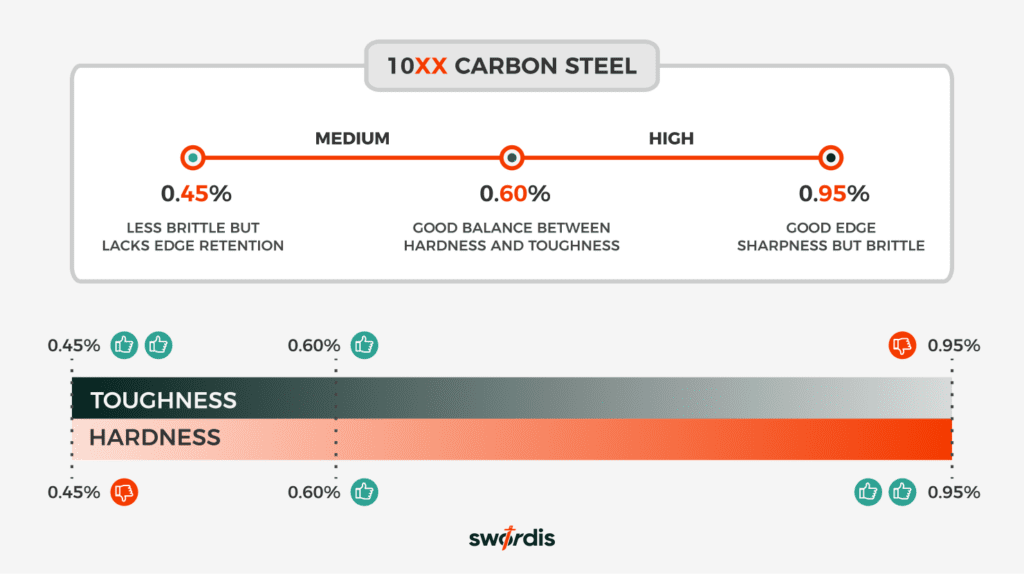

However, carbon steel in sword making can be broadly divided based on their carbon content into the following:

- Medium carbon steel: 0.45 to 0.60% carbon (Softer, but more flexible)

- High carbon steel: Higher than 0.60% carbon (Harder, but more brittle)

The carbon content in steel is indicated by the last two digits and determines the strength of the blade.

Some of the most popular carbon steel used in sword making include:

1045 carbon steel

1045 steel has enough carbon for a functional blade, making it softer, easier to forge, and affordable.

It’s ideal for iaido practice, a Japanese martial art using unsharpened katanas, and is also perfect for entry-level katanas due to its flexibility and resistance to breaking.

Examples of 1045 Carbon Steel Katanas

1060 / 1065 Carbon Steel

1060 or 1065 carbon steel has many benefits including affordability, ease of forging, durability, strength, and flexibility.

Due to its balance in properties, it is often a favorite for functional swords used in demonstrations and training.

Examples of 1060 Carbon Steel Katanas

1095 Carbon Steel

Due to the high carbon content, blades forged from 1095 high-carbon steel are known for their hardness and excellent edge retention.

It is therefore recommended for professional-level swords and collectibles that require a sharp edge for tameshigiri or display.

Examples of 1095 Carbon Steel Katanas

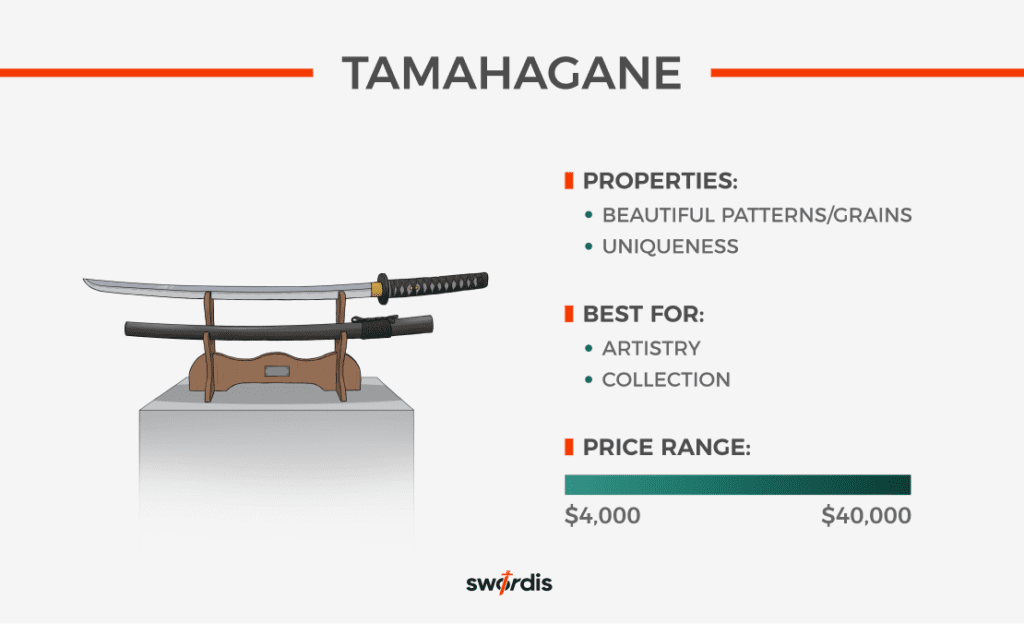

2. Best for Tradition – Tamahagane Steel Katana

Since the Heian period (794-1185 CE), traditional Japanese swords were exclusively made from tamahagane due to Japan’s lack of large iron deposits.

Even as other nations advanced in metallurgy, Japan continued using tamahagane, making it a hallmark of traditional Japanese swords. For this reason, many Japanese sword enthusiasts say tamahagane steel is the best for a katana.

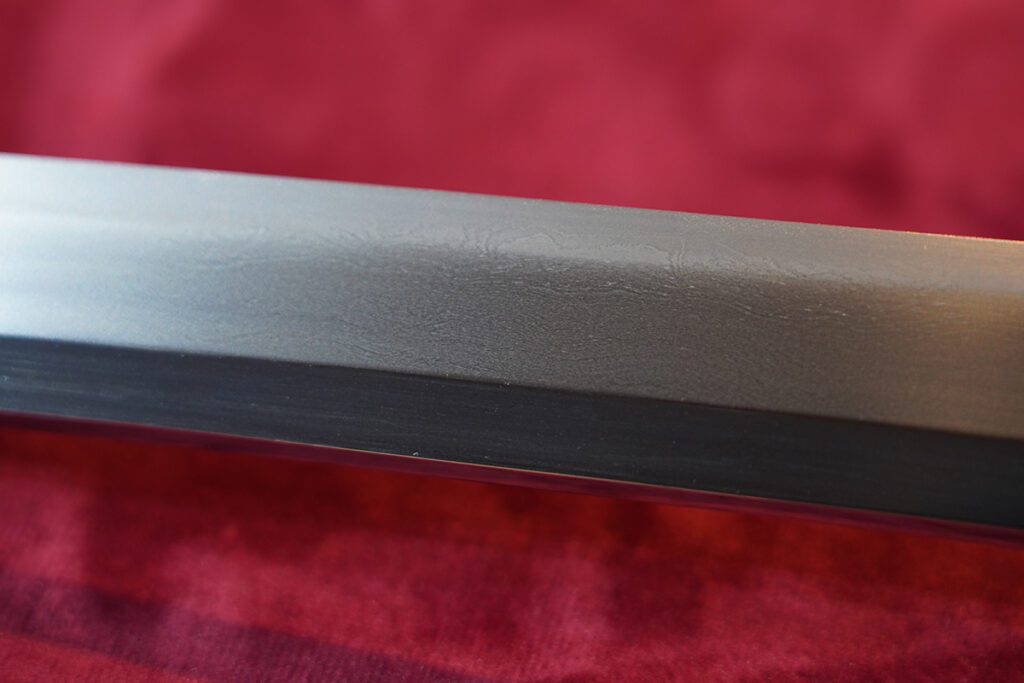

Tamahagane steel is considered imperfect and needs to go through a more complicated process that creates a distinctive pattern with various layers and grains.

Due to the time and effort required to produce tamahagane steel, the resulting blade is often more expensive than most. In fact, it is said that the highest quality tamahagane can cost 50 times more than ordinary modern steel.

However, thanks to advances in metallurgy, tamahagane steel is not necessarily superior in terms of performance when compared to modern steels such as spring steels, tool steel, and high-carbon steel. Instead, its appeal lies more in its historical and cultural value.

3. Best for Display – Damascus Steel Katana

There is often some confusion when it comes to Damascus steel.

True Damascus steel or Wootz steel originated in India around 500 BCE where its original production methods were lost to history.

Meanwhile, the Damascus steel we know today is pattern-welded Damascus steel, a modern reproduction designed to mimic the appearance of Wootz steel.

It is made by folding steel to achieve the desired patterns and etched with acid to enhance its visibility.

Although similar in appearance, the pattern-welded version today often lacks the legendary sharpness and flexibility often touted of Wootz Damascus steel.

Despite being outperformed by other modern steels in terms of edge retention, flexibility, toughness, etcetera, pattern-welded Damascus steel blades are unmatched in its visual appeal, making it the ideal steel for display pieces.

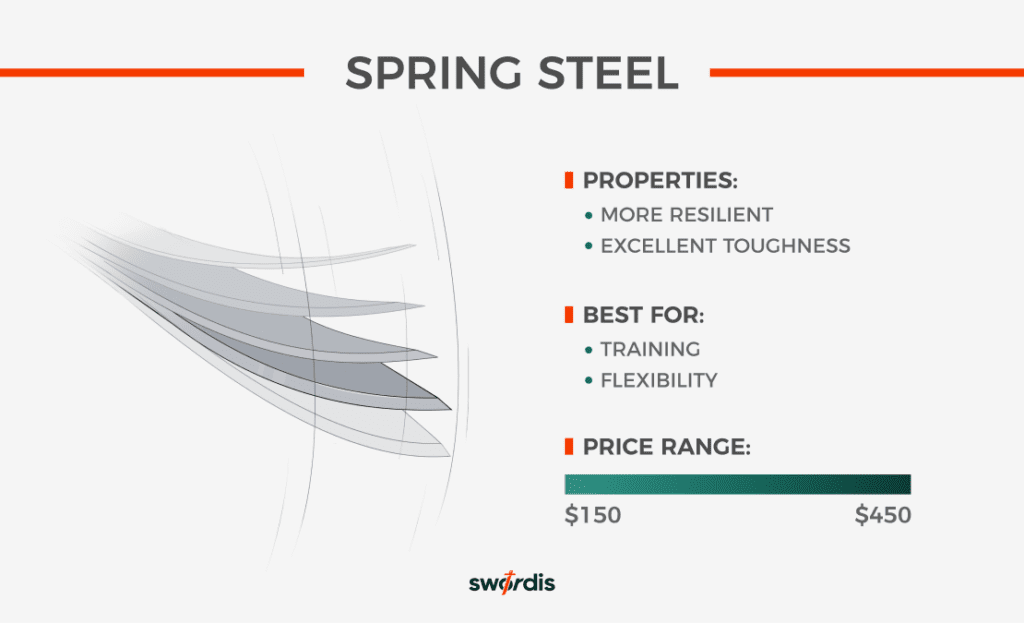

4. Best for Flexibility – Spring Steel Katana

Besides carbon, spring steel not only contains carbon, but is also alloyed with a combination of other elements such as manganese, nickel, chrome, and more. However, one of the common elements in spring steels is silicon which contributes to its durability and flexibility.

In sword making, some of the common spring steels used are:

5160 Spring Steel

5160 spring steel is a chromium-carbon alloy with added silicon and manganese, making it tough and impact-resistant.

Blades made from 5160 can handle heavy use without breaking or chipping and have some rust resistance due to the chromium.

Example: Dragon King’s Autumn Leaf Katana

9260 Spring Steel

9260 spring steel contains 0.60% carbon with extra silicon, giving it high flexibility and allowing it to spring back after extreme bending.

While it’s more prone to rust, 9260 blades can last a long time with proper care.

Example: Shadow Dancer’s Dotanuki High Performance Katana

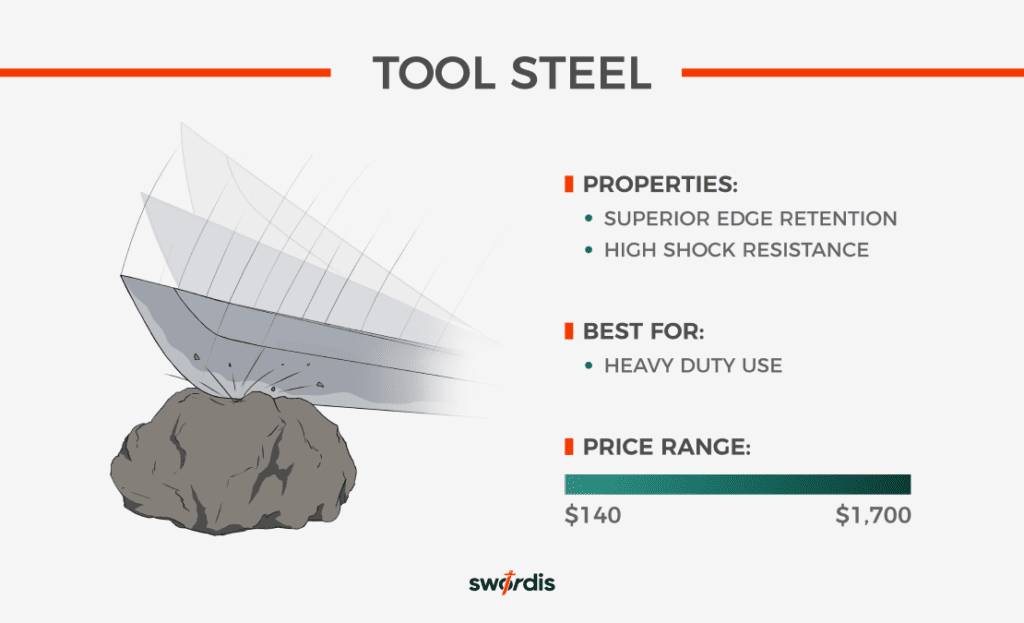

5. Best for Heavy Cutting – Tool Steel Katana

As a modern steel, tool steel offers many benefits, such as impact resistance and toughness, which have resulted in its use in tools, industrial machinery, and equipment, as well as automotive and aerospace components.

Due to its attributes, it is an increasingly popular material for sword-making to produce blades with excellent edge retention, hardness, and durability. Some of the most popular include:

T8/T10 Tool Steel

T10 tool steel is similar to 1095 high-carbon steel. With 1.0% carbon and added silicon, T10 offers excellent edge retention and strength, making it popular for affordable, heavy-use katanas.

T8, with 0.8% carbon, is slightly less durable and therefore less commonly used.

Example: T8/T10 Steel Katanas

S5/S7 Steel

S5 tool steel, known for its high impact resistance, is commonly used in concrete breakers and die casting, making it ideal for rigorous sword use.

While S7 tool steel offers greater hardness, harder isn’t always better; S5 provides a balanced mix of hardness and toughness, excelling in impact and specific wear resistance.

Examples: S5 Steel Katana Collection

L6 Bainite

L6 is another tough alloy steel that is commercially available for sword making. The addition of elements such as nickel and chromium adds to its toughness and shock resistance.

Although tough, it has a lower carbon content, resulting in inferior edge retention if compared to T10 steel. However, if properly treated, it is highly durable and flexible.

Examples: L6 Bainite Steel Katanas

Since specialized heat treatment is required for L6 Bainite, S5 and S7 steel swords, they are harder to find and more expensive compared to the more accessible and affordable T10 steel swords.

Conclusion

Each with unique strengths and trade-offs, the choice of “best” steel for a katana ultimately depends on one’s intended use, preferences, and needs—whether it’s the durability of tool steel, authenticity of tamahagane, or visual allure of pattern-welded Damascus steel.