The Best Sword Steel Doesn’t Exi… (Or Does It?)

NO AI USED This Article has been written and edited by our team with no help of the AI

Since steel is the backbone of any sword, choosing the right type is crucial. The unique properties of each steel type impact the resulting blade’s sharpness, edge retention, flexibility, and durability. For this reason, there is no single steel type that is the best overall.

However, it’s not just the steel that matters. Think of it like two cotton t-shirts made of the same material but with different designs. Similarly, the quality of a sword depends on how the blade is crafted and treated.

As Walter Sorrells, a swordsmith with over two decades of experience specializing in Japanese swords, puts it, “The single most important factor in the quality of an edge tool is heat treating.”

In this article, we explore the different types of steel used in swords, examining their unique properties, and helping you choose the best steel for any scenario.

If you’d like a more detailed explanation of sword steel types, feel free to watch the video below.

What Does Steel Actually Mean for Swords?

Swords are primarily made from steel, an alloy which combines iron and carbon. The carbon content in steel, which typically ranges from 0.02% to 2% by weight, determines the steel’s strength and hardness.”

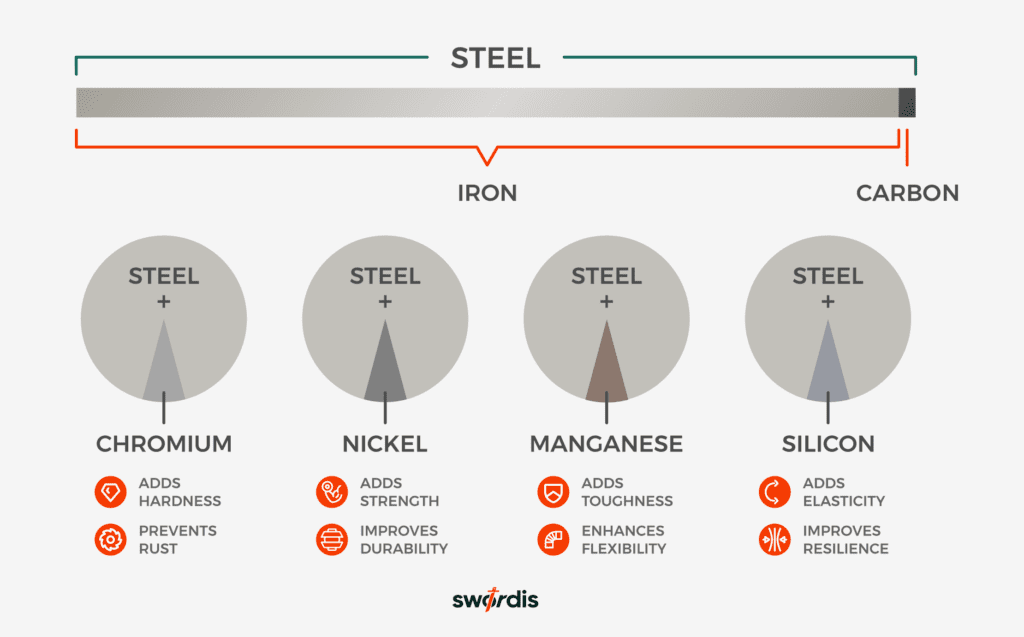

In addition to iron and carbon, steel can be alloyed with additional elements such as chromium, nickel, manganese, and silicon to enhance its properties. Each element improves key properties including:

| Property | Key Benefit | Best For |

|---|---|---|

| Strength | Prevents bending/warping | Combat swords, heavy-use blades |

| Hardness | Maintains a sharp edge | Cutting competitions, sharpness priority |

| Toughness | Absorbs shock without breaking | Functional training, high-impact training |

| Corrosion Resistance | Protects against rust/oxidation | Outdoor, display, ceremonial swords |

After learning what to look for in a sword, it all comes down to your budget. Fortunately, it is possible to find both functional and decorative swords ranging from just $100 to a few thousand dollars.

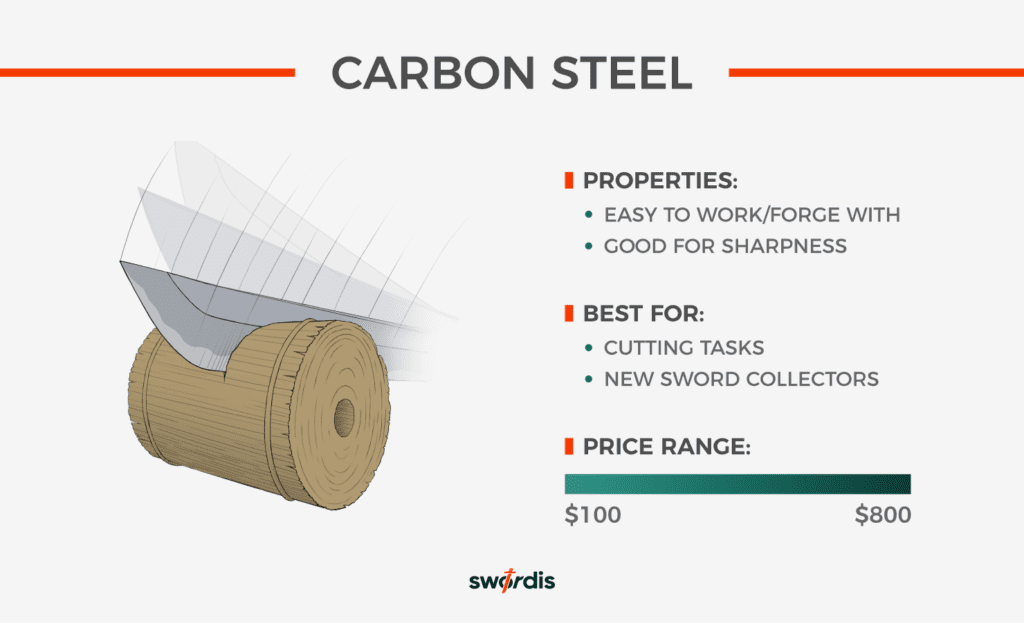

1. Best Overall: Carbon Steel

Many might disagree, but for those new to sword collecting, carbon steel can be said to be the best overall as it offers a balance of qualities at affordable prices.

Carbon steel is also often the top choice for many sword makers as it is the easiest to shape and the resulting blades are known for their strength, durability, and edge retention.

However, carbon steel blades require more care and maintenance, including regular cleaning and oiling to prevent rust.

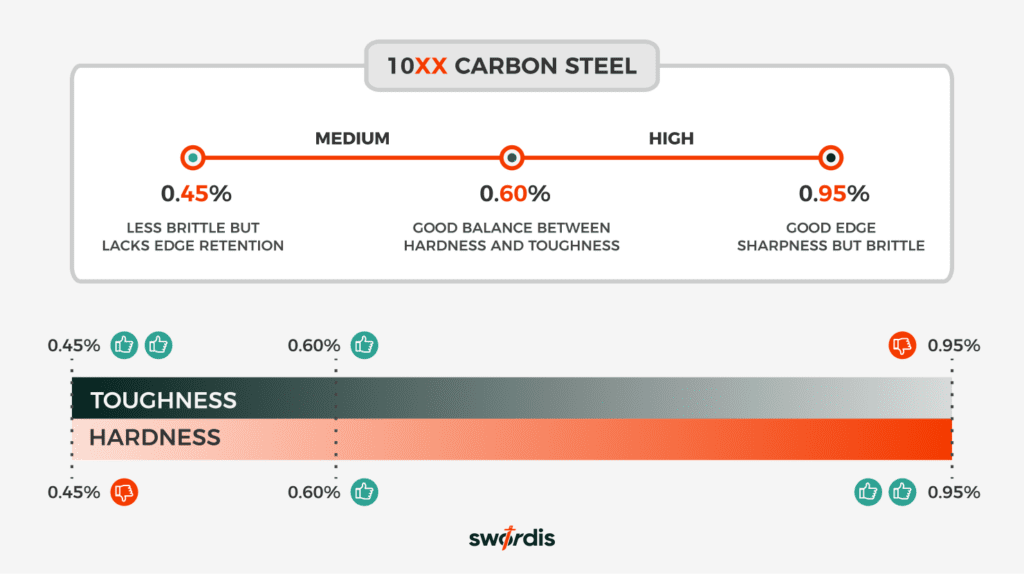

In sword making, the preferred carbon content ranges from 0.45% to 0.95% as it reacts well to heat treatments like hardening and tempering. The carbon content is indicated by the last two digits in 10XX.

Carbon steel can also be further categorized based on their carbon content:

- Medium carbon steel: 0.45% to 0.60%

- High carbon steel: >0.60%

Although a higher carbon content results in harder steel, it also makes it more brittle—meaning it’s more likely to chip or crack under impact if not properly tempered.

The three most popular types of carbon steel used in swords are:

- 1045 carbon steel: Ideal for iaido practice (a Japanese martial art that trains using unsharpened katanas). Being the most affordable option, 1045 blades are also suitable for entry-level katanas.

- 1060/1065 Carbon Steel: A step up from 1045, blades made from 1060 and 1065 carbon steel offer reliable performance while remaining affordable. They are popular for practical cutting swords due to their balance of durability, hardness, and edge retention.

- 1090/1095 carbon steel – With higher carbon content of 0.90% and 0.95%, these blades are extremely sharp and have excellent edge retention. However, they can be more brittle and less forgiving of mistakes, especially in longer blades. They are therefore often recommended for experienced practitioners.

2. Best for Display – Stainless Steel

Stainless steel is the go-to choice for kitchen knives, appliances, and decorative items due to its shiny and attractive appearance, low maintenance, and affordability. These advantages can be attributed to the presence of chromium which forms a protective layer on the surface.

While great for a display piece, stainless steel is rarely used in functional swords. Instead, blades made from carbon steels and their similar materials are those that truly shine.

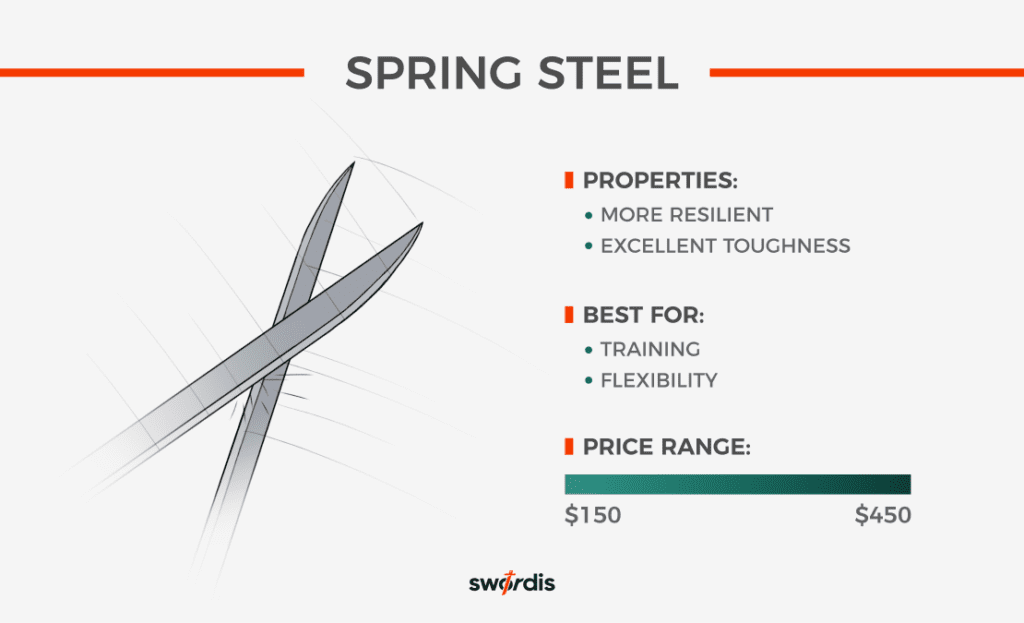

3. Best for Training and Stage Combat – Spring Steel

Spring steel is known for its resilience—meaning its ability to return to its original shape after any bending. This makes it ideal for swords used in combat scenarios or demanding practices.

Besides carbon, spring steels are often alloyed with other elements, one of which is silicon, an essential component in their composition. (Info point)

Some popular examples include:

- 5160 Spring Steel – Comprising 0.60% carbon, 0.7-1.0% chromium, and 0.15-0.3% silicon, this steel offers excellent toughness and flexibility, ideal for swords and large knives designed for heavy impact.

- 65Mn Spring Steel – A Chinese steel known for toughness and affordability, it’s similar to 1065 carbon steel with added manganese, making it great for spring-tempered swords.

- 9260 Spring Steel – With 2% silicon, this steel is highly resilient, often returning to shape after near 90-degree bends. Known for its durability, it’s rarely broken, even under extensive testing.

The steel types mentioned above are cost-effective and easy to work with, making the resulting swords more affordable in the low to mid-range category.

Next are more complex steels that are harder to work with due to their unique properties.

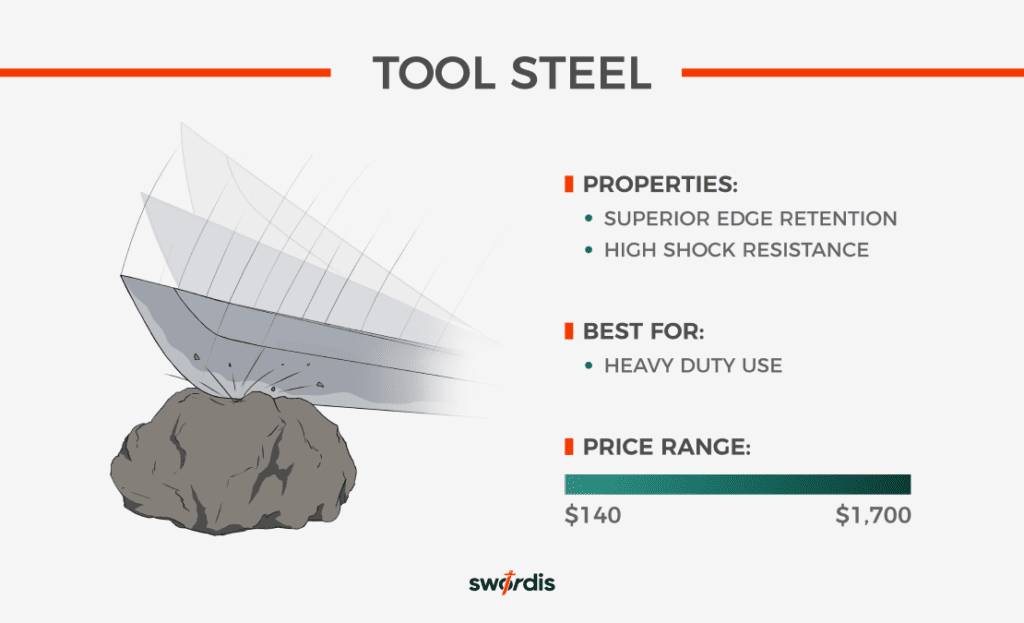

4. Best for Heavy Duty Use – Tool Steel

Designed to withstand heavy use and extreme conditions, tool steel is typically used in tools like drills and punches for their high shock resistance and exceptional hardness.

Due to its attributes, it has gained popularity in sword making and is used in high-performance swords as it can also hold a sharp edge.

Some of the most popular types of tool steel are:

- T10 & T8 Steel – These popular tool steels are similar to 1095 high-carbon steel. T10 contains 1.0% carbon and silicon, enhancing edge retention and strength, making it widely favored for swords. T8, with 0.8% carbon, is slightly less durable and thus less preferred.

- L6 Bainite – This premium tool steel is known for its toughness and excellent edge retention, even with heavy use. When crafted properly, L6 Bainite blades are among the most resilient.

- S5 & S7 Tool Steel – Ideal for high-impact applications, S5 is commonly used in concrete breakers and die casting due to its exceptional impact resistance. S7 also offers high impact toughness and shock resistance, with slightly higher strength and hardness than S5.

Note that S7 tool steel has slightly higher ratings in hardness and wear resistance compared to S5. However, harder isn’t always better as S5 is easier to work with when heat treating.

Performance-wise, S7 excels in cutting while S5 is superior in shock resistance.

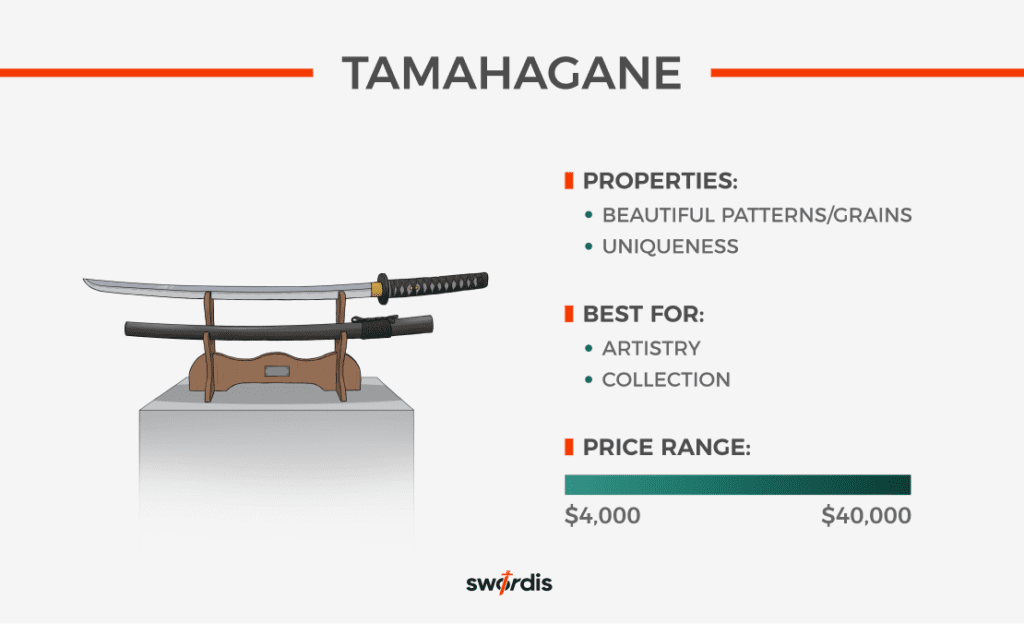

5. Best for Tradition – Tamahagane or Damascus Steel

While “traditional steels” isn’t a specific category of steel, it is the most historically significant in sword making. Examples include Tamahagane steel and Wootz steel—often referred to as original Damascus steel.

- Tamahagane Steel is the traditional steel used in Japanese sword making.

- Wootz Steel/Damascus Steel originated in India where it was first produced. It was then widely used and traded in Damascus, Syria.

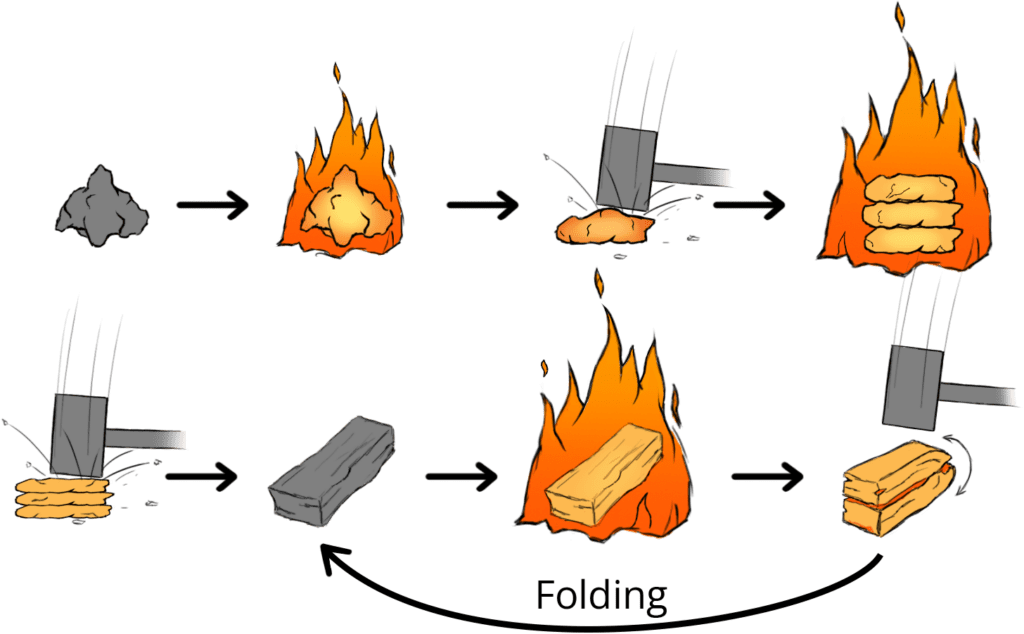

Tamahagane steel is considered imperfect and needs to go through a more complicated process that creates a distinctive pattern with various layers and grains. To use it, the swordsmith must transform it by repeatedly heating, pressing, and folding the steel until it becomes a solid, unified piece.

Both tamahagane and wootz steel are rarely used in modern sword making with the exception of Japan where tamahagane steel is still utilized.

Due to the extensive effort required to forge these steels, there are only a few swordsmiths worldwide who work with them, making these swords rare and expensive, ranging from at least $2,000-$3,000 dollars for a replica up to $10,000+ for authentic tamahagane Japanese swords.

With the advent of modern sword making, modern Damascus steel (also known as pattern-welded steel) has emerged.

It is created by folding one or two different types of steel to produce a distinctive pattern. For example, folding 1060 with 1095 carbon steel.

However, there’s a trade-off. The more the steel is folded, the more carbon is lost, resulting in a softer and less durable blade. Therefore, modern damascus (folded) steel is not recommended for a functional sword.

Conclusion

Choosing the right steel for a sword depends on individual needs and preferences. Each type of steel has its unique strengths with the craftsmanship being equally important.

Most sword collectors own swords made from various types of steel, proving there isn’t a single best option. Understanding these differences will help you make a more informed and confident decision when selecting the next sword.