Is Damascus Steel Good for Katanas?

NO AI USED This Article has been written and edited by our team with no help of the AI

Damascus steel has gained a renowned reputation over the course of history, giving rise to numerous legends about its extraordinary qualities. Yet, there is an ongoing comparison between ancient and modern Damascus steel and debates on whether or not it is a lost art.

This article attempts to delve into the myths surrounding Damascus steel, examining its properties, and weighing its pros and cons before determining its suitability for katanas.

What is Damascus Steel?

Damascus steel, often referred to as Wootz Steel, is a type of high-carbon crucible steel that is believed to have originated in India, where it was first produced. It was widely used and traded in Damascus, Syria.

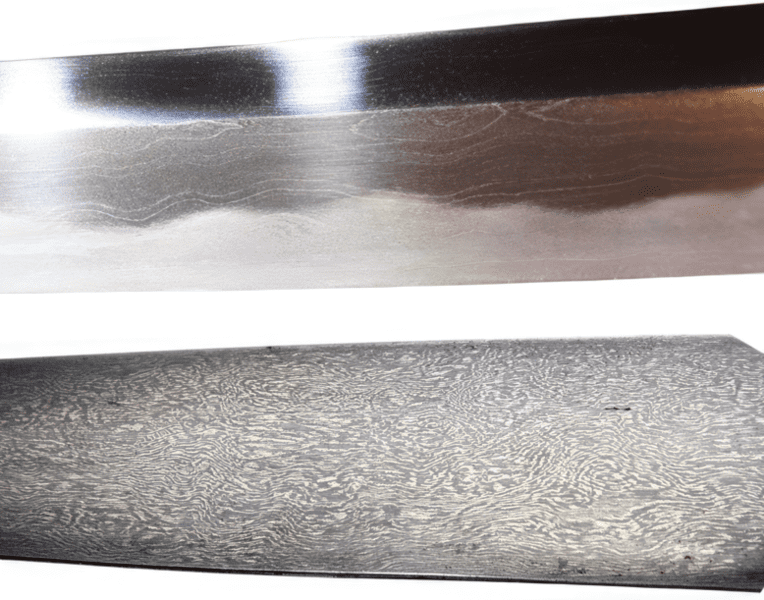

The process of making crucible steel involves melting iron, steel, and other elements with charcoal in a closed crucible, allowing for high carbon absorption. This results in a blade with exceptional hardness and a distinctive, wavy pattern reminiscent of flowing water.

Historians disagree on how Damascus steel got its name, but that isn’t all. While most believe that it was first produced around 500-600 CE, others say that it dates as far back as 1500 BCE.

Today, it is used to describe two possible options:

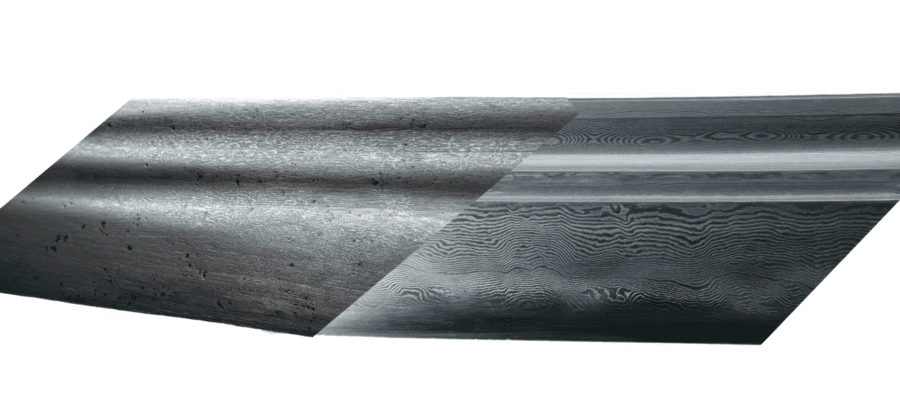

- Pattern welded: Known as modern Damascus steel, it is made by layering two steel types and hammering them together at high temperatures. For example: 1095 and 1060 Carbon Steel

- Pattern welded and Etched: This type of Damascus steel is just like any other steel but with the characteristic pattern etched using acid on the surface to enhance the visibility of the patterns. In some cases, these patterns may fade over time.

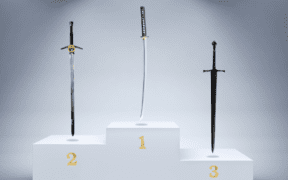

Modern vs “True” Damascus Steel

There is some debate when it comes to Damascus steel. While some believe that the technique of producing true Damascus steel is a lost art, others claim to have rediscovered how to produce it.

In 1998, Verhoeven and Pendray were believed to have rediscovered the composition that would create this steel.

While rare, there are some swordsmiths that use “true” damascus steel today. However, this is mostly seen in Middle Eastern blades.

Is “True” Damascus Steel Used on Katanas?

There are no historical examples of traditional Japanese samurai katanas being made out of real Damascus Steel. Instead, they’re made of tamahagane, a type of steel turned into a functional blade made from iron dust.

Though it’s not traditional Damascus steel, there are some sellers at Swordis like Z-SEY and ShadowDancer that forge katanas from a type of crucible steel.

Is Modern Damascus Steel Good for a Katana?

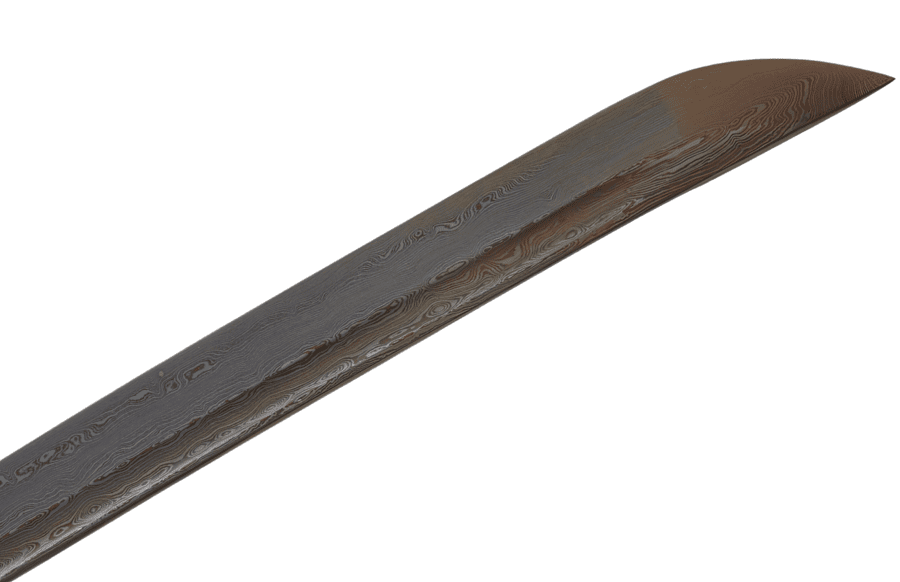

While pattern-welded Damascus steel is a good choice for those who prefer the characteristic aesthetics, the folding process which introduces air gaps with each fold means that it is less functional and more suited for decorative purposes. Therefore, these blades are not superior in terms of cutting, durability, or edge retention.

Additionally, modern Damascus steel katanas are not recommended for those who prefer a katana with an authentic appearance. Some Iaido classes also do not permit the use of untraditional-looking blades.